Ridgid’s Pro Gear gen 2.0’s all terrain,

large mobile toolbox doesn’t come with mounting brackets like the individual boxes so if

you want to remove the wheels and hang the box, you’ll have to wait until early 2023

when the brackets become available. So given Ridgid’s lack of foresight,

I’m going to build my own large toolbox brackets. Just keep in mind if you build

your own brackets it voids the warranty… I start with a scrap piece of 1/2” plywood…

trace the top of a bracket that came with one of the smaller boxes, and mark the position of

the top mounting hole with a screwdriver or punch. The mounting holes need to be

11” apart, so I measure 11”, and then use a punch to mark the location

of the bottom mounting hole. Line up the punch mark with the hole in the bottom of the

bracket and trace the outline of the bottom. Now to connect the lines.

I’m

making two brackets at once, but it may be easier to make one and then repeat

the process using the first as a template. For the second bracket once again I’ll trace it

out and using a square, make sure the mounting holes line up. Honestly though, it doesn’t need

to be perfect since I’ll be putting a level across the brackets to get the tops lined up. That

way the box isn’t crooked when I mount it . I mark a line on each bracket 1 1/8” from the

top since that’s where the brackets will attach, take everything outside, clamp down the

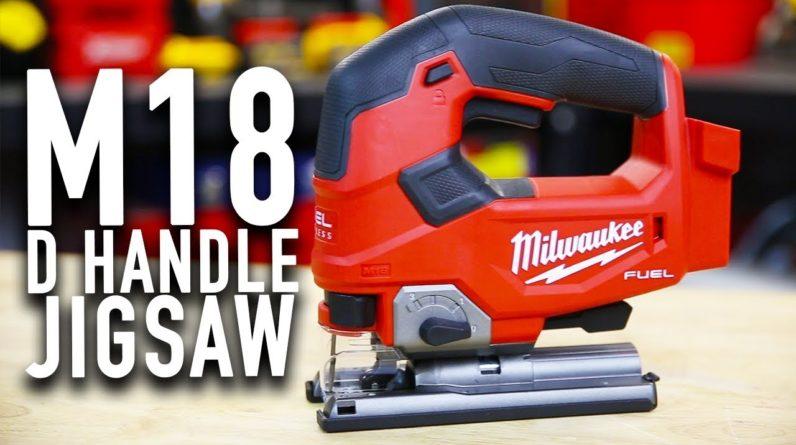

plywood, and use a jig saw to cut out the forms. The edges don’t need to be perfect at this

point since I’ll sand out rough edges later. Unfortunately as soon as I got set up, it started to lightly rain. Power tools

and rain? Never a good combination. Yes, it looks like I’m

holding two large…. Moving on. For the back of the brackets I grab two 2×2’s, which are actually

1.5×1.5, measure 13” inches, and cut them. The tips of each bracket need

to tapper from 3/8” at the tip, up to the plywood’s 1/2” thickness as shown.

I draw the taper onto the sides of each form so I don’t take off too much material, and

then use an orbital sander to make the taper. Once that’s done I can smooth

out any rough edges on the forms. I test them out to make sure

they insert into the box the same distance and make any necessary adjustments.

Since I’m making two brackets at once, I line up the tops along the non-tapered edges clamp them

and drill 1/8” holes at the marks 11” apart. To make assembly easier, I mark the center of

the 2×2’s, that would be at 3/4 of an inch, and the center of the brackets on the line marked

1 1/8 inches from the top, which was previously marked, and put some temporary holding

screws into the 11” holes I just drilled. Before attaching though make sure the

tapered side is on the same side as the 2×2 or else the brackets won’t

slide into the box properly. On each bracket I mark and pre drill

three 1/8” holes through the center of the brackets, add a counter sink, and

temporarily put in a few 1 5/8”screws. Now I can remove the temporary screws I put

into the mounting holes, which are 11” apart. I use a 5/8” spade bit to make shallow

indents at the holes marked 11” apart and that will accommodate #42 flat washers,

which are 5/8 in diameter with a 1/4” hole. Predrill 1/8” holes through the

mounting holes and into the 2×2’s. Label which pieces go together.

Mark around the 2×2 for reference, and now I can remove the 1 5/8” screws.

For added strength, apply wood glue to the 2×2 and reattach the parts using the 1 5/8”

screws, then do it again on the other bracket. Clamp or screw the top and bottom of each

bracket, wipe any excess glue and let them dry. 24 hours and a wardrobe change later it’s

time to install them according to the mounting instructions that came with my other boxes.

Basically, I figure out where I want them. Draw a line at the top of the 2×2.

Put a

level across it and mark the other stud. Mark 16” on center. Then draw a

line down each stud 16” on center. Mark center on the 2×2. Clamp the first

bracket and check that it’s level vertically. Then I clamp and level the second bracket and

attach both brackets using 3.5” screws and washers. Now If I didn’t have clearance behind

the studs to clamp, I’d have attached the first bracket and then put a level across the top and

mounted the second bracket. Had I needed more holding strength I also could have replaced one

or two of the three 1 5/8” screws between the 11” apart mounting holes with countersunk, 3.5”

screws to penetrate the studs, but it really wasn’t necessary in this case.

The box is going to

store my pneumatic nailing guns and accessories, which aren’t that heavy. Touche Ridgid!

Once I get around to it, I’ll review these Ridgid boxes and the link will appear in the

upper right hand corner of this video. While the boxes don’t hold quite as much as my DeWalt

boxes, they’re just as durable, less expensive, and I like the new mounting feature since it

doesn’t require any special mounting racks. I hope this information has been

helpful. If it has, please do me a favor and hit that “like” button as if

you had to build your own brackets because RIDGID missed their product sales deadline, and

subscribed if you like.

Thanks for watching! Ridgid’s Pro Gear gen 2.0’s all terrain, large mobile toolbox doesn’t come with mounting

brackets like the individual boxes so if you want to mount the wheels. Mount the wheels? No!

RIDGID’s mobile system 2.0 XL moo… Mooble. RIDGID’s progrill… RIDGID’s mo… Ha! I’ll be right

back…. Brrrrrrr…. Let’s try it again. Every time I look at these brackets now I’m just going to

see [bleep]s. Touché RICKET… RICKET. Oh man!.