Hey there guys, Paul here from TheEngineeringMindset.com. In this video we're

going to be learning all about the electronic expansion valve. We'll look at how they

work, where to locate them, and why you should use them. Today's video is brought

to you by our partners over at Danfoss who have

kindly sponsored this video. Danfoss is committed to

providing the very best solutions for a wide range of applications, including chillers, cold

rooms and heat pumps. These solutions include their series of high quality, electronic

expansion valves, which are approved for use

with all common refrigerants, as well as a wide range of

capacities and pressure ranges. The compact and durable design

make them easy to install while enabling significant

energy and cost savings. You can check out their entire range of electronic expansion

valves by following the link in the video description below. Electronic expansion valves are used in refrigeration systems to

precisely control the flow of refrigerant into the evaporator. You can find these on

everything, including VRF units, inverter mini splits, heat pumps, chillers, AHU coils, et cetera. Now, we've previously covered how thermal expansion valves work.

These are very common in

refrigeration systems, but they are nowhere near

as efficient or precise as an electronic expansion valve. If you haven't watched the

video on how these work, then I highly recommend you do so. Links are in the video description below. Electronic expansion

valves are an evolution on the thermal expansion valve. They are much more sophisticated and allow the refrigeration system to operate much more

accurately and efficiently. You usually see the electronic

expansion valves listed with the acronym of either EEV or an EXV. They both mean the same thing.

It just varies by manufacturer. There are many benefits to using an electronic expansion valve and I've listed some of the

main points on screen now. The focus though, is usually that by using an electronic expansion valve you're going to reduce

the energy consumption of the refrigeration system, as well as gaining much

better performance. What do electronic

expansion valves look like? There are many different designs for an electronic expansion valve and I've put a few examples on screen now so you can see how

their appearance varies. The difference in design

depends on the type of system, the refrigerant used, and the

pressure it's working with. As you can imagine, a small split AC unit isn't going to need the same valve as a high pressure industrial application. So the design is going to vary, although the basic working principle

is essentially the same.

Main parts of the

electronic expansion valve. As we just saw, there are

many different designs for electronic expansion

valves, but we're going to focus on a simplified design to help

you with your base knowledge. This design uses a permanent

magnet stepper motor. At the head of the valve, we

have the stepper motor body, which contains the copper coils. These are used to generate

an electromagnetic field, which will be used to

control the valve's position. Sitting concentrically

within the main body of the stepper motor

is a permanent magnet. This permanent magnet is affected by the electromagnetic field of the coils and the change in polarity

of the electromagnetic field will cause the permanent magnet to rotate. Attached to the permanent

magnet there's a shaft. Now, some designs will use a gear assembly between the motor and the shaft, but as we're only looking

at a simplified example, we're going to stick to

a directly coupled shaft.

On the shaft is a thread. This thread sits within a holder which is attached to the valve body. At the end of the shaft is a valve needle. Then we have the valve seat which the needle moves into and out of to close and open the valve and control the flow of refrigerant. We'll also have some

temperature and pressure sensors to take measurements of the refrigerant in order to calculate the superheat. These will be connected to the controller. The controller is then

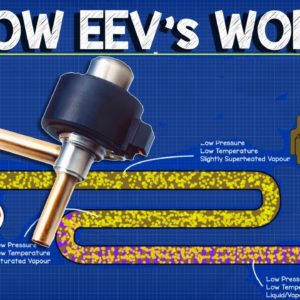

connected to the stepper motor and will tell it how much to open or close to maintain the correct superheat. So how does an electronic

expansion valve work? If we have a look at a

typical refrigeration system you can see the main parts

being the evaporator, the compressor, the condenser,

and the expansion valve.

The evaporator collects

all the unwanted heat from the building and transfers

this into the refrigerant, which causes the refrigerant

to boil and evaporate. The compressor then sucks in

this evaporated refrigerant, which is a low pressure, low temperature and slightly superheated vapor. It then compresses this

into a smaller volume, which causes it to be a high pressure, high temperature, super-heated vapor. The refrigerant then

moves to the condenser where the unwanted heat is

pulled out of the refrigerant and rejected into the atmosphere.

This causes the refrigerant

to condense into a liquid so when it leaves the condenser it will be a high pressure, medium

temperature, saturated liquid. It then passes down into

the expansion valve. The expansion valve causes

a pressure difference between the condenser and the evaporator. It holds back the high

pressure liquid refrigerant and decides how much to let

through into the evaporator.

As the high pressure

liquid refrigerant bursts through the small gap

between the valve seat and the needle, it drops in pressure. This will result in some of

the refrigerant vaporizing and the rest will continue

through as a liquid. If you want to visualize this, it's similar to a water

bottle spray nozzle. As you pull the trigger, the high pressure liquid is

forced through a small orifice into a much lower pressure atmosphere, which causes the water to become

part liquid and part vapor. This mixture of liquid

vapor refrigerant is sprayed into the evaporator,

where it will absorb heat from the air or water

which surrounds the outside of the pipe which forms

the evaporator coil. In this case we have a fan which is blowing air

across the evaporator coil. As the refrigerant passes

through the evaporator coil it is exposed to thermal energy which will cause it to undergo

a complete phase change from a liquid to a saturated vapor still at a low pressure and temperature.

During this change, there'll be little to no temperature change

because of the latent heat and instead it will increase

in entropy and enthalpy. As thermal energy is still

being applied to the vapor towards the exit of the evaporator, there is no liquid leftover

to change into a gas form, so the refrigerant will

instead start to increase in temperature and become superheated. After the evaporator, we'll

find a pressure transducer and a temperature sensor which

constantly take measurements and sends this data to the controller. Not all electronic expansion

valves will use this method. It really depends on the

manufacturer and the system. Some simple ones will

use a single thermistor at the evaporator outlet. Some will use two thermistors, one at the inlet and

another one at the outlet and then use a temperature

differential as the superheat. But we're going to focus on the pressure and temperature method in this example, as it's a very reliable method and one you'll likely come

across in the real world. The pressure is measured and

converted by the controller using stored data for the

refrigerant being used in the system to find the

saturation temperature.

This is then compared to the

actual temperature measurement. The difference between the two

is the operating superheat. The controller then decides whether the expansion valve should open to let more refrigerant

into the evaporator or close to reduce the amount entering. Once decided, the controller

then sends electrical signals to the expansion valve stepper

motor to energize the coils and create an electromagnetic

field and vary its polarity. This forces the permanent

magnet to rotate clockwise or counter-clockwise depending

on the polarity generated. Each time a signal is sent, the permanent magnet will rotate

a fraction of a revolution to provide very accurate

adjustments to the superheat. The shaft, which is connected

to the permanent magnet, will also rotate and as it

does so the threaded section inside the holder will cause

the assembly to be pulled down.

As the assembly is pulled down, it will cause the valve

needle to reach the seat, reducing the gap between and restricting the flow of refrigerant. When the signal is sent to open the valve, the assembly will rotate

in the opposite direction and the threaded section

pulls the assembly up. This opens the valve and moves

the needle away from the seat allowing more refrigerant to flow. The controller is

constantly taking pressure and temperature measurements

and sending signals to adjust the valve position

to suit the current load. When the cooling load

increases, the refrigerant within the evaporator is

going to boil off much quicker and the suction line pressure

and temperature will increase. The expansion valve senses this and opens to allow more refrigerant in. When the cooling load decreases, the refrigerant will boil off more slowly and the suction line pressure

and temperature decreases. The expansion valve

will then begin to close to allow less refrigerant

into the evaporator and maintain the correct superheat.

Just before we go, I want

to give one last shout-out to our partners over at

Danfoss, remind you to check out their electronic expansion

valves by following the link in the video description below. Okay guys, that's it for this video. Thank you very much for watching. I hope you've enjoyed

this and it's helped you. If so, please don't forget

to like, subscribe and share. If you have any questions, leave them in the comments section below. Also, don't forget to follow us on Facebook, Twitter,

Instagram, Google Plus and check out our website,

TheEngineeringMindset.com. Once again, thanks for watching..