In the world of HVAC, there’s a mantra that seasoned technicians often share: sometimes, the job isn’t finished until you’re back at it again. This theme rings true in the latest YouTube episode titled “Going Back to a Call a Week After I Fixed It!” Join us as we delve into the intricacies of HVAC work, revisiting a particular house filled with energetic dogs where an earlier repair has led to unexpected issues. Our HVAC expert takes viewers along on this intriguing callback, finding out why the cooling system is once again struggling to perform. From troubleshooting the blower to inspecting capacitors, and even managing the chaotic backdrop of barking pups, this video captures the unpredictable nature of the HVAC life. Tune in as we explore not only the technical details but also the lessons learned along the way, emphasizing the importance of thorough checks and precautions in this challenging field. Whether you’re a fellow technician or simply curious about the day-to-day realities of HVAC work, this post will take you on a journey through the complexities of keeping cool under pressure.

Understanding Callback Scenarios in HVAC Services

“`html

Encountering callbacks in HVAC services is part of the job, and understanding the dynamics of these scenarios can greatly enhance our troubleshooting skills. In this instance, the customer reported a cooling issue with a unit I recently serviced. Upon arrival, the tranquility of the situation was disrupted by a lively pack of dogs, distracting me from the initial diagnostics. Such unexpected elements are common and can affect our ability to assess problems quickly. I noticed the condenser fan motor wasn’t operating as expected, which prompted a thorough check of the entire unit’s components. This highlights the importance of not only examining the obvious issues but also considering potential error sources that can stem from recent repairs.

As the assessment progressed, I encountered an electrical anomaly with the capacitor, reflecting the intricacies of HVAC systems. The unpredictable nature of equipment failure led me to trace the wiring closely, as overlooked connections could easily lead to callbacks. In addition, evaluating refrigerant levels during this process is crucial, especially since previous refrigerant charges can often go unnoticed. Here’s a quick summary of essential callback factors:

| Factor | Description |

|---|---|

| Electrical Issues | Check all connections thoroughly; improper wiring can lead to multiple issues. |

| Refrigerant Levels | Monitor for leaks and ensure proper refrigerant levels are maintained. |

| Unit Conditions | Assess the overall health of the unit and its components after repairs. |

“`

Troubleshooting Techniques for Common HVAC Issues

“`html

When troubleshooting HVAC issues, it’s essential to systematically assess various components of the system. In the recent callback, the condenser fan motor was replaced, but the unit was still not cooling. A quick check revealed that—despite everything being plugged in—there was no power to the motor, which initially may have been masked by the chaos of barking dogs. To ensure reliable operation, always verify that the contactor is properly wired and that the capacitor has been discharged before testing. If it’s not functioning as expected, you should consider the following steps:

- Confirm Power Supply: Check circuit breakers and fuses to ensure power is reaching the unit.

- Inspect Wiring: Ensure all connections are secure and free from damage.

- Test the Capacitor: Measure its health with a multimeter to avoid further failures.

During my inspection, I also checked the refrigerant pressures. External temperature can impact readings, so it’s crucial to adapt your approach based on current conditions. If you suspect refrigerant leaks, like the one I’ve encountered before with R-422, be prepared to address it promptly to maintain system efficiency. Always document any signs of past issues and keep an eye out for recurring patterns during these assessments. Here’s a quick summary of additional checks that can be helpful:

| Check Point | Symptoms | Recommended Action |

|---|---|---|

| Capacitor Checking | Unit won’t start | Discharge & test with multimeter |

| Refrigerant Levels | Reduced cooling output | Check connections & refill if necessary |

| Wiring Connections | No power at unit | Inspect & repair damage if found |

“`

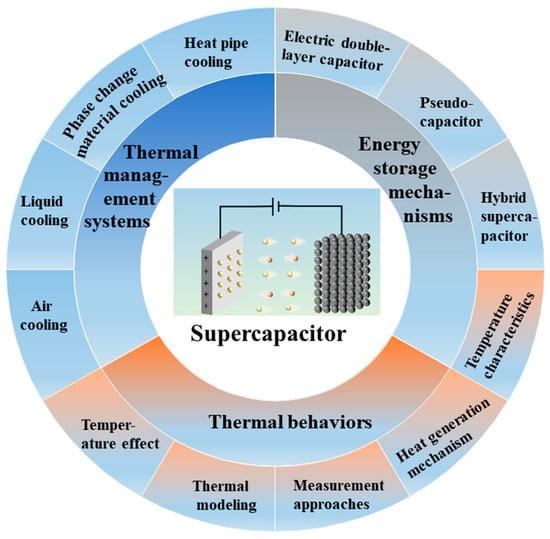

The Importance of Proper Capacitor Management

html

Managing capacitors effectively is crucial for ensuring the longevity and efficiency of HVAC systems. During my recent call back to the dog-filled house, I encountered a situation where the newly installed condenser fan motor was not running as expected. A quick inspection revealed no power coming from the capacitor. This situation serves as a reminder of the importance of discharging capacitors before conducting any tests. Failing to do so can lead to erroneous readings and potentially dangerous situations. The integrity of capacitors is vital since they regulate voltage and assist in the starting and running of motors, thus affecting the entire system’s performance.

Proper capacitor management also includes regular inspections and replacements to avoid unexpected breakdowns. In my recent visit, what started as a simple check quickly turned into a deeper investigation when I discovered that the wiring connected to the contactor might have caused the issues. By ensuring that capacitors are functioning correctly and maintaining connections, HVAC professionals can mitigate future problems. The following table summarizes key practices for effective capacitor management:

Practice

Description

Discharge Capacitors

Always discharge capacitors before checking to avoid risky measurements.

Regular Inspections

Schedule routine checks to ensure capacitors are functioning at optimal levels.

Proper Documentation

Keep detailed records of capacitor performance to spot trends and issues early.

Recommendations for Future HVAC Repairs and Maintenance

html

For effective HVAC repairs and maintenance, it is essential to adopt a proactive approach. Here are a few key recommendations to consider:

- Regularly check and replace filters to ensure optimal airflow and system efficiency.

- Perform routine inspections of electrical components such as capacitors and contactors, as small issues can lead to larger problems.

- Schedule seasonal maintenance to address potential issues before peak seasons, keeping systems running smoothly.

- Always discharge capacitors before testing them, as this simple step can prevent injuries or equipment damage.

Additionally, it is crucial to maintain clear communication with clients regarding past repairs. Documenting all previous issues, including specifics like refrigerant types and any signs of leaks, enables technicians to diagnose future problems with greater accuracy. Consider implementing a maintenance log that tracks service dates, replaced parts, and client observations:

Date

Service Performed

Notes

MM/DD/YYYY

Condenser Fan Motor Replacement

Initial issue of not cooling; check capacitor next time.

MM/DD/YYYY

Refrigerant Top-Up

Suspected leak; monitors pressure regularly.

To Wrap It Up

As we wrap up this insightful journey through the world of HVAC, it’s clear that even seasoned professionals are reminded of the unpredictable nature of their work—from the chaos of barking dogs to unexpected equipment challenges. Our recent call-back showcased not only the importance of thorough diagnostics but also a crucial lesson: always discharge your capacitor before checking it. This video serves as a valuable reminder that no two days are ever the same in the field.

If you found this behind-the-scenes look beneficial, we invite you to share your thoughts and join our growing community of HVAC enthusiasts. Your support inspires us to create more training content and share the joys and challenges of the HVAC life. Don’t forget to hit that like button and subscribe for future updates! Until next time, stay cool and keep those systems running efficiently. Catch you in the next video!