– I'm Craig Migliacchio, and in this HVACR training video we'll learn if

you can check the refrigerant charge on a service call in a mini split unit? Secondly, why is there only one access port on the vapor line

? So we

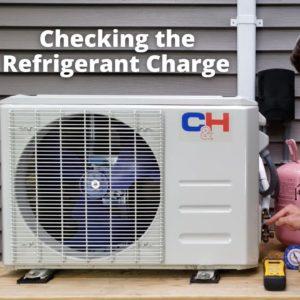

are going to discuss this in this video. In this video, we are using

a Cooper & Hunter Inverter Heat Pump System. So it is a single zone unit, however it is an inverter system so it

can increase or decrease the compressor speed and also the efficiency of the EEV metering equipment.

It controls the external fan as well as the

internal fan. And what we usually do is, on a standard single and double speed unit, we check based on a metering device to determine the overheating on the vapor line and the sub-cooling charge on the liquid line . So I want to take you over to a standard single speed unit and just show you

what superheat and subcooling are all about, before we get back to this unit here. So we're near a single speed unit and the first thing you'll notice is that there's a port on the liquid line as well as a port on the vapor line. In a mini split system, we have only the vapor line port. Now in this case, in a

single-speed system, you have high-pressure, high-temperature subcooling liquid refrigerant

going through this liquid line at the air conditioning load. And

this is not the case in a mini split system. You have a low pressure, low

temperature liquid refrigerant. And you don't have that access port. But never mind, let's just

understand this for a second.

If you have a fixed size orifice like this one on

a piston or capillary tube indoor air handler or evaporator coil, you need to check the refrigerant charge with superheat in a single speed unit. And so what you would do,

you take the line temperature which is 63, and then you look at the pressure on your vapor meter. You bring it up to the inner ring R410A for saturated temperature, in this case it is 43 degrees. So you take the line temperature from

which the set temperature is subtracted to get the total superheat. So 43 is subtracted from 63. So we get a total superheat of 20 degrees.

To find out what your

target should be, you need to measure the temperature of an outdoor dry valve and an indoor wet valve. And if this actual superheat is higher than your target, then you

need to add refrigerant. If your actual superheat

is lower than your target, then you need to remove a little bit of the refrigerant

. But never mind, if

you have indoor coil with a

txv metering device like this , you need to check refrigerant charge with subcooling. And on a mini split unit

you don't have TXV, you have EEV. But anyway,

with a txv like this, we're going to measure our subcooling. So we'll check our pressure,

which is 295 psi, we bring it to the saturated temperature

of R410A which is 94 degrees, and we take the line temperature

minus 94 degrees which is 89 degrees, and we

have five degrees. There is subcooling. So you compare it to the target subcooling which is given on the rating plate, and in this case it is 10 degrees. So five degrees below our target which means it has less charge if we have

a TxV on the indoor coil. And on our Mini Split,

we have our EEV actually mounted in the outdoor unit , not in the indoor unit.

So there is only one metering device in a mini split heat pump,

and that is in the external unit. So now let's go back to our inverter mini split system. So we

have come to the outdoor mini split system, and it is an inverter unit, so it

makes efficient use of electrical energy to circulate the refrigerant throughout the system

and

also airflow to transfer the heat. And so you

transfer heat, whether you are in the air conditioning

system or in the heating system. And you see we

can hook up our vapor meter to check our superheat. But what I

want you to remember is this, and what technicians are also doing is applying their knowledge to single speed

units for superheat and subcooling and

try to put that in a mini split, and You

really can't do that.

But I'll show you a few

things we can do, because what we're going to

do is we'll check our superheat at low

fan speed, medium fan speed, high fan speed, and turbo speed. But I want you to

keep in mind that in a txv a single speed unit, what it

does is that it controls the amount of refrigerant that is

going into the indoor coil by itself and you have

a fixed orifice like in a piston or capillary tube. Once again, it only controls what is going into the refrigerant coil. In an inverter mini split system, or another great one, you have the EEV as the metering device.

And it doesn't control the superheat in the indoor coil by itself. What happens is that it

is controlled by a control board which consists of several temperature sensors. So it has an outdoor temperature sensor, it has a saturated temperature sensor, it

has a sensor next to the metering device. It also contains, in the indoor unit, another temperature sensor for the room. It has another coil temperature sensor. So it goes as far as choosing

how much it has to open this path from the inside. It's kind of open-ended. I know you can't see it, but we'll have

to see it in another video. But it is like opening or closing the path here

depending on all the inputs of temperature and

also depending on the programming language. You also have an indoor fan that can be slowed down or speeded up.

And even if you set it manually like you have

set it manually at low speed, medium speed, at high speed, what will happen is that the system itself will make some adjustments in it. And so it's

controlling electrically efficiently and adjusting all the time. And at the same time, you have a compressor that is being controlled by this board

in terms of rotations per second. So it can be at low rotations or at high rotations per second as far as the amount of refrigerant being moved through the system. At the same time, you have this external fan. And that can be at low speed or high speed

depending on the wind on the outer coil. And the only control

you have a little bit is the internal unit where

you can set the amount of air you want. However, when you

set it manually, the system that's actually in the indoor unit will control the wind speed a little more or less than your manually

set fan speed.

So from all this it can be said that we

are not dealing with single speed units here. So what I'm going

to do is turn on the system. And we're going to check out superheat at

low fan speed to medium fan speed, high

fan speed, and also turbo, just to get a sense of what's going on here. So in the indoor unit we

set a low fan speed and we have a temperature of 63 degrees on the vapor line

for T1. And our pressure measurement is about 147 psi. So we're measuring if we bring that into the saturated ring of R410A, we're measuring about 51 degrees. And so what we do is

subtract 51 from 63 and we have a total of 12 degrees of superheat. The problem with this is that we have nothing to compare. And so we don't know

how much the superheat should be. And, likewise, we have four components, the compressor, the EEV, the external fan, and the internal fan, that are going to affect our total superheat measurement. But still, let's go ahead and check on our medium fan speed.

So now we are on medium fan speed and we have

a vapor line temperature of 64 degrees. We have

a saturated temperature of about 55 degrees. So we subtract 55 from 64, and we have a total of nine degrees of superheat. Now I'll go ahead and

speed up the fan speed. It's been a few minutes now. We have set our wind speed to

high. The vapor temperature on the line is 61 degrees, and we have a saturated temperature here showing about 57 degrees in the lower part

. So we subtract 57 from 61, and we have a total of four degrees of superheat. Now it is okay for a system, for a mini split system, to have low superheat or

even no superheat because

there is an accumulator on the side of the compressor. And so the job of the accumulator is to protect the compressor so that it just lets the

vapor refrigerant in.

So even if you have saturated

and liquid refrigerant at the bottom of this accumulator, until you overfill it with

refrigerant, these tubes

will continue to draw vapor refrigerant into the compressor here and there. So in a standard system

that doesn't have an accumulator , it

can be dangerous to have little or no superheat. But in the case of a mini split, it is really good and efficient too with less superheat. So now we have the

indoor fan set on turbo mode.

And so it's on a lot of airflow. And so we have

a vapor line temperature of 63 degrees and we have a pressure of about 150. We

bring this to the saturated temperature of R410A, we're looking at about 52 degrees. So we subtract 52 from 63, and we have

about 11 degrees of total superheat left. So the main point of this is like say even if you

set the thermostat inside at a very low temperature compared to the actual temperature, what's going to happen is that this

control board

can adjust the amount of refrigerant here, this amount of refrigerant

Can adjust the fan speed regardless of what is set on your indoor unit. So unless you have

a way to stabilize the fan speed of the outdoor unit, the fan speed of the indoor unit, the rotation of the compressor and where is the pin in the EEV, basically

the capacity and position of the refrigerant passing through there, if

There's no way to stabilize it, to a certain known amount, no way to really test the charge

because we don't have a target superheat

to set the thing against.

It just doesn't exist. And the whole point is that the control board will control the amount of superheat at any given time based on the bus temperature input and program logic to precisely control the refrigerant and air flow

. So now you see our superheat is still low, it is 53 out of

56, and we have three degrees of superheat left. Now we have two degrees of superheat. Secondly, a mini split system can run at a very low superheat

, and that's all right, as a mini split system has a rotary compressor and always has an accumulator on the side. The accumulator protects the compressor from the ingress of liquid refrigerant. And hence the major cause of compressor failure is overcharging. So if

you are trying to test charge and put refrigerant on the base to superheat

, you can accidentally

overcharge the system and allow liquid refrigerant to get in and jam the rotary compressor and therefore , it could be bad.

So you don't want to do that. And so you just have to remember that you don't have a target to superheat, you can't check subcooling on a unit like that

. And so you have to, if you have a problem

as if this unit is operating at a saturated temperature below 32 degrees, it's probably a low refrigerant

charge problem because maybe someone did

n't connect the flare connectors correctly. Maybe they

didn't tighten them properly, but it could also be

that the EEV is turned off or the thermistor near it is

basically bad and is giving a bad input signal to the control board

.

And control telling it to stop. This could also be a problem. But most of the problem, most of the time when you have a low

saturated temperature here, is from a low refrigerant charge. Or if you notice that you

have an extremely high superheat, once again, you may have a low refrigerant charge and you just need to turn off the unit, drain all the

refrigerant, and then weigh it, basically With this you will test its pressure, fix leaks.

You will do a pressure test, vacuum, and

fill the vacuum with the correct amount of refrigerant per unit based on the factory charge on the outside unit, and the total line length. So you have

to measure the refrigerant in this kind of system. You

cannot check the charge of a running inverter system and adjust it while it is running

. If you

want to know more about mini split system make sure to click the link given below in details. I also have articles I

wrote on mini split systems on our website at acservicetech.com, and I hope you

enjoy yourself. We will see you next time on "AC

Service Tech Channel".