Every spring and summer, we get a lot of phone

calls from customers saying their AC isn’t working. A good portion of those calls are for a common

repair. Their capacitor has failed. If your technician has told you that your

capacitor has failed, it’s definitely one of those items you’re going to want to replace;

And I’m going to tell you why in this video. If this is your first time watching our channel,

please click subscribe down here on the bottom right.

And, if you click that little bell next to

it, you’ll be notified of all our videos as they come out. I want to give a fair warning to everyone

watching this. If you’re watching this video with the intention

of changing your own capacitor, they carry a lot more voltage than the typical 240 volts

that runs the air conditioner. Capacitors can and will shock you even when

the power is turned off. Serious injury and death can occur, as high

voltage doesn’t mix well the human body.

So, this video is not to teach anyone how

to install or replace a capacitor. There are other YouTube creators that will

explain it for you. I recommend having a real HVAC technician

handle this repair as they know how to discharge the capacitor properly so no one gets injured. A capacitor is a storage bucket of electrons

that is constantly giving itself up for the motor it supports. And, they don’t make them like they used

to! Capacitors made in the 60’s 70’s and 80’s

were designed to last a long time. As a technician, I still come across these

late model air conditioners and I’m amazed their capacitors are still running just fine. That’s kind of unheard of these days. Capacitors made today are typically designed

to last five to ten years.

There are definitely some brands of capacitors

that are made better than others, and it’s up to your HVAC technician to find those good

brands and use them in the best interest of you, the customer. I’ve seen caps that only lasted two years! I know of certain brands of air conditioners

that are installed brand new, and two or three years later, we are replacing the capacitor.

Then an HVAC company comes out and replaces

theirs with a cheap or less proven brand, and it gave out in a short amount of time,

with no warranty on the item. So, the customer has to buy another one. That’s frustrating for the customer, but

not for the HVAC company. They get to keep charging $200 plus dollars

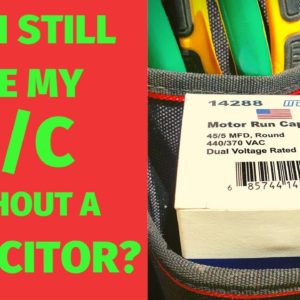

to keep your AC running every other year. We use MARS brand capacitors, because they

are made in America and I personally believe they last longer than the others.

There are several other brands to use out

there, but we don’t switch it up and use those other brands just because we happen

to be near an HVAC supply store that sells cheaper capacitors. Most of the motors in your air conditioner

can’t run without a good capacitor. Like I said, they support these motors. They help the motor start and run efficiently. Some people have gone out to their air conditioner

and noticed the fan wasn’t spinning on their AC like normal. So, they get a stick or something to reach

into the fan shroud and try to manually get the fan blade to start spinning. And it works now! This is a classic sign that the capacitor

for that fan motor is bad, and a good example to you why these motors can’t start and

run efficiently without a good capacitor.

And we can’t just put any ol’e capacitor

in there either. It needs to be the exact size recommended

by the manufacturer. If it isn’t, the motor might start, but

will operate out of balance. It causes an uneven magnetic field around

the motor, which can make the motor noisy, make it work harder (raising the cost to run

it,) or just cause the motor to burn out altogether.

Now, there are differences in a typical dual

run capacitor that normally comes in your AC and a start capacitor that can be added

on to your system either at the manufacturer or at your house by a technician. I’ll explain those in a different video

and try to attach that video when I make it at a later date. But for the purposes of this blog, I wanted

to answer this question my best friend Matt asked me the other day, and I thought it would

make a good question to answer for other people out there.

If your capacitor has failed, please don’t

try to run that part of the system. It’ll only cause more damage to the system,

which might force you to replace a bigger, pricier part, or your entire system. So just be patient. Hopefully your technician has one on their

truck already. They usually will. Some of you folks out there changing these

out on your own better be careful. Capacitors carry a lot of power and will strike

before you know it. So, that’s just my last bit of warning for

you DIY’ers if you try to navigate this repair on your own. If you are buying these parts online because

of price, sure they might be cheaper, but that’s nothing compared to getting injured

or possibly ruining a more expensive part because you didn’t hook it up right. If you’re paying the average price of $100

to $300 dollars for a capacitor from your technician, (depending on which part of the

country you’re in,) it’s because you’re paying for that company to have the right

one on their truck and install it right now for you.

If this is your first time watching our channel,

please click subscribe down here on the bottom right. And, if you click that little bell next to

it, you’ll be notified of all our videos as they come out. Thanks for watching and we’ll see you on

the next video..