When it comes to maintaining the efficiency of HVAC systems, understanding the tools of the trade can make a significant difference in performance and longevity. Among these tools, the vacuum pump stands out as a critical component for achieving optimal vacuum levels during installation and service. However, the question of “what size vacuum pump for HVAC?” often arises, leaving many professionals and DIY enthusiasts in a whirl of confusion. This article delves into the essential factors that influence vacuum pump sizing, helping you navigate the complexities of selecting the right pump for your specific needs. Whether you’re a seasoned technician or a curious homeowner, join us as we explore the ins and outs of vacuum pump sizing, guiding you toward informed decisions that can enhance the efficiency of your HVAC systems.

Choosing the Right Vacuum Pump Capacity for Your HVAC Needs

When selecting a vacuum pump for your HVAC system, it’s essential to consider the capacity that matches your specific requirements. The size of the pump is critical for effectively removing moisture and contaminants from the refrigerant lines, which can help maintain system efficiency and prolong the lifespan of your equipment. A pump with a capacity between 3 CFM and 10 CFM is typically suitable for most residential HVAC applications. However, if you are dealing with larger systems or more complex setups, a higher capacity may be needed to ensure thorough evacuation.

To help you in your decision-making process, consider the following factors:

- System Size: Match the vacuum pump capacity with the size of your HVAC system.

- Usage Frequency: For regular use, a larger capacity may save you time and increase efficiency.

- Type of Refrigerant: Different refrigerants may require different levels of evacuation.

| System Type | Recommended CFM |

|---|---|

| Residential AC | 3 – 5 CFM |

| Commercial AC | 5 – 7 CFM |

| Large Chillers | 8 - 10 CFM |

Understanding the Correlation Between Pump Size and System Efficiency

When selecting the appropriate vacuum pump size for HVAC systems, understanding the relationship between pump size and system efficiency is vital. A pump that is too small may struggle to achieve the necessary vacuum levels, leading to longer operating times and increased energy consumption. Conversely, an oversized pump can cause rapid cycling and increased wear on system components. To optimize efficiency, it is essential to consider the specific requirements of your HVAC system, including the volume of air needing to be evacuated and the desired speed of the evacuation process.

Moreover, maintaining a balanced approach is crucial. Here are some factors to consider when determining the right pump size:

- System Volume: Larger systems generally require more powerful pumps.

- Pumping Speed: The required evacuation speed can influence pump selection.

- Application Type: Different applications may call for tailored pumping solutions.

- Energy Efficiency Ratings: Opt for pumps with high efficiency to reduce operational costs.

| Pump Size (CFM) | Recommended System Size (Ton) | Typical Applications |

|---|---|---|

| 2 CFM | 1-2 Ton | Small Residential Units |

| 3 CFM | 2-4 Ton | Standard Residential Units |

| 5 CFM | 5-8 Ton | Mid-Sized Commercial Units |

| 10 CFM | 10+ Ton | Large Commercial Systems |

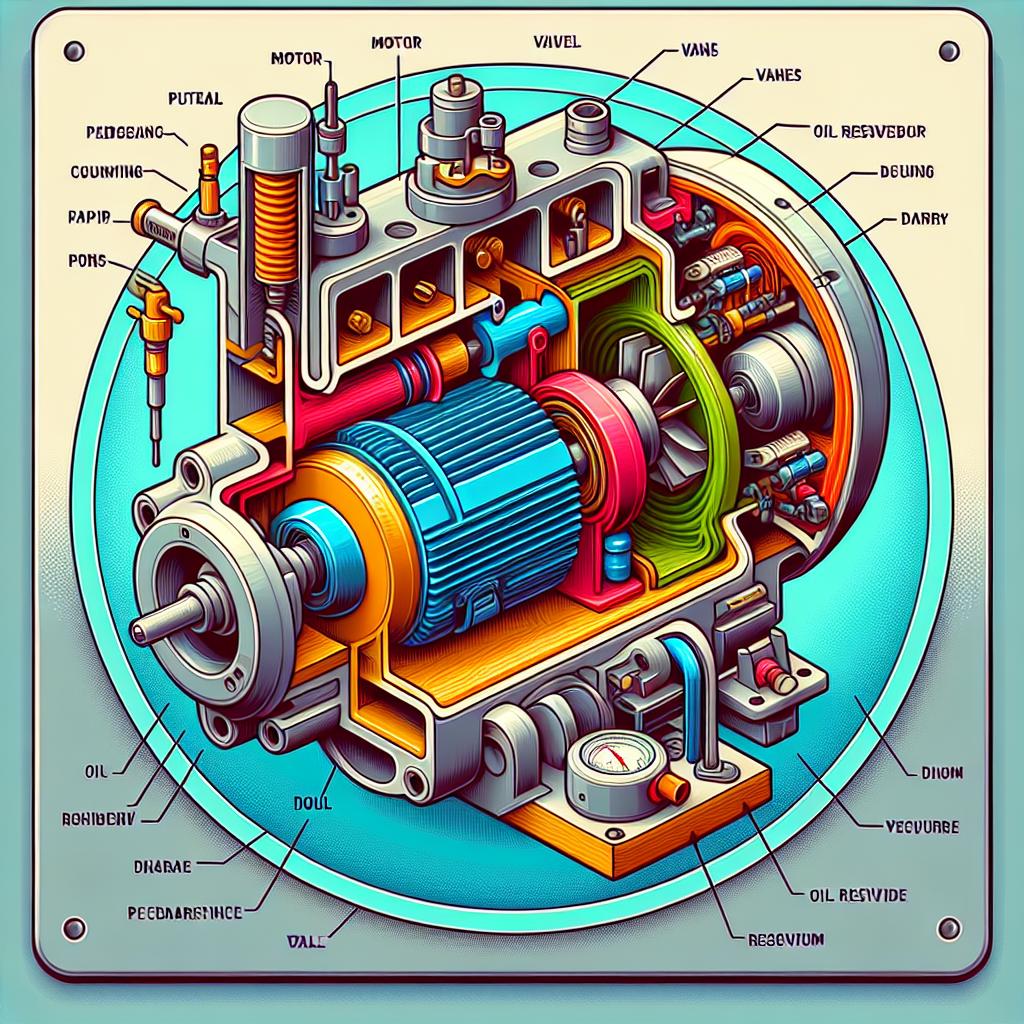

Key Features to Look for in an HVAC Vacuum Pump

When selecting a vacuum pump suited for HVAC applications, there are several key features that play a crucial role in ensuring optimal performance and efficiency. First and foremost, consider the pump’s capacity measured in CFM (cubic feet per minute). A higher CFM rating allows for quicker evacuation of air and moisture from the system, which is essential for effective performance. Additionally, the ultimate vacuum level is critical—look for pumps that achieve deep vacuum levels, typically below 250 microns, to ensure all contaminants are effectively removed before charging the system.

Another significant aspect is the oil-free operation feature, which not only simplifies maintenance but also prevents contamination of refrigerants. Moreover, examine the port sizes and configurations, as these impact compatibility with various HVAC systems. Features such as built-in thermal protection can prevent overheating during prolonged use, enhancing the pump’s longevity. consider the noise level of the pump; quieter models tend to improve user experience, especially in residential settings. Below is a concise summary of these features for quick reference:

| Feature | Importance |

|---|---|

| CFM Rating | Quicker system evacuation |

| Ultimate Vacuum Level | Ensures removal of contaminants |

| Oil-Free Operation | Prevents refrigerant contamination |

| Port Sizes | Compatibility with various systems |

| Noise Level | Improves user experience |

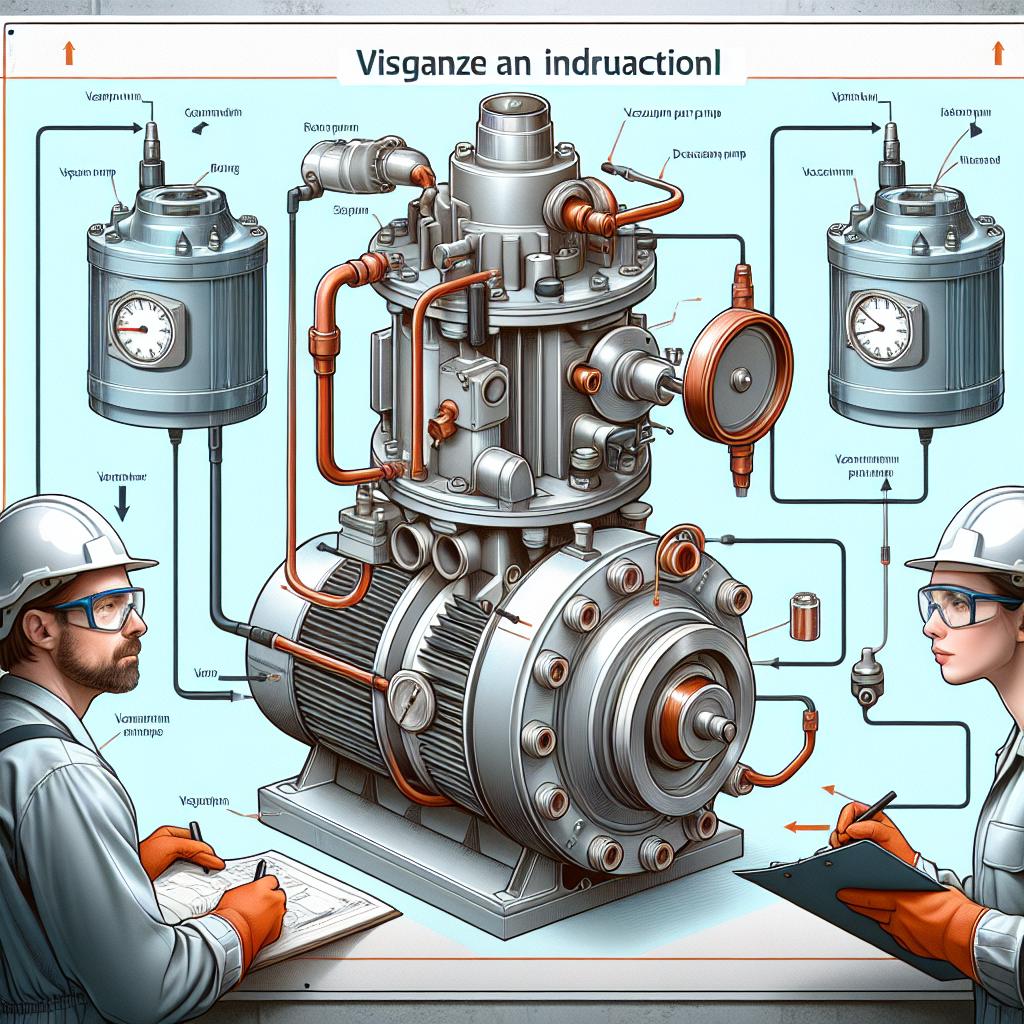

Best Practices for Vacuum Pump Maintenance and Operation

To ensure the longevity and efficiency of your vacuum pump, adhering to best practices for maintenance and operation is essential. Regularly check oil levels and quality, as contaminated oil can lead to significant damage to the internal components. Always use manufacturer-recommended oil to avoid compatibility issues. It’s also crucial to keep your pump clean; check for dust and debris accumulation in filters and cooling fins. A clean pump operates more efficiently and reduces the risk of overheating. Other effective measures include:

- Routine inspections: Schedule periodic checks to identify any abnormal sounds or vibrations.

- Temperature monitoring: Keep an eye on the operating temperature of the pump to prevent overheating.

- Seal integrity: Regularly inspect seals and replace them if wear is detected.

When operating a vacuum pump, proper usage is just as important as maintenance. Proper training for operators can significantly impact the pump’s performance; they should understand how to connect and disconnect the pump properly, avoiding sudden changes in pressure that could lead to damage. Ensure that the vacuum system is appropriately sized and configured for your specific application to maximize efficiency. Consider the following operational tips:

| Tip | Description |

|---|---|

| Start-ups | Always run the pump for a few minutes without load to ensure everything is functioning correctly. |

| Venting | Naturally vent the vacuum when turning off the pump to prevent damaging the motor. |

| Load Management | Avoid operating the pump beyond its load capacity for optimum performance. |

Q&A

Q&A: What Size Vacuum Pump for HVAC?

Q1: What is the main function of a vacuum pump in HVAC systems?

A1: Vacuum pumps play a crucial role in HVAC systems by removing moisture and air from the refrigeration system during installation or servicing. This process is essential for ensuring optimal performance and efficiency, as any traces of air or moisture can lead to system inefficiencies and potential damage.

Q2: How do I determine the right size vacuum pump for my HVAC needs?

A2: The right size vacuum pump depends on several factors, including the size of the system, the volume of refrigerant, and the time you’re willing to spend evacuating the system. Generally, a pump with a capacity of 2-3 CFM (cubic feet per minute) is suitable for residential applications, while larger commercial systems may require pumps rated at 4 CFM or more.

Q3: What does ‘CFM’ mean, and why is it important?

A3: CFM, or cubic feet per minute, measures the volume of air the pump can remove from the system in one minute. It’s important because a higher CFM allows for quicker evacuation, leading to less downtime and more efficient servicing. However, excessively high CFM rates can also lead to unnecessary wear on components, so finding the right balance is key.

Q4: Are there different types of vacuum pumps? Which one is best for HVAC?

A4: Yes, there are several types of vacuum pumps used in HVAC applications, including rotary vane, diaphragm, and piston pumps. Rotary vane pumps are the most common choice for HVAC technicians due to their reliability, affordability, and effectiveness in reaching deep vacuum levels, usually around 500 microns or lower.

Q5: Is there a specific micron level I should aim for?

A5: Yes! When evacuating an HVAC system, the goal is often to reach a vacuum level of 500 microns or lower. This level helps eliminate moisture and ensures that no non-condensables are left in the system, which could impair efficiency and lead to compressor failure.

Q6: What are the consequences of using an undersized vacuum pump?

A6: Using an undersized vacuum pump can lead to prolonged evacuation times and an incomplete vacuum, resulting in residual moisture or air in the system. This could ultimately compromise the system’s performance, increase energy costs, and shorten the life expectancy of HVAC components.

Q7: Should I consider the brand or manufacturer of a vacuum pump?

A7: Absolutely. Opting for well-established brands or manufacturers can provide peace of mind regarding the quality and reliability of the vacuum pump. Reputable brands often come with warranties, customer support, and robust replacement parts availability—all factors that can save you time and money in the long run.

Q8: Can I rent a vacuum pump instead of buying one?

A8: Yes, for those who only occasionally service HVAC systems, renting a vacuum pump can be a cost-effective solution. Just ensure that you select a pump that meets the CFM requirements for your specific application, and check its condition before use.

Q9: What should I keep in mind when operating a vacuum pump?

A9: When operating a vacuum pump, it’s crucial to follow the manufacturer’s instructions, including checking oil levels and changing oil when necessary. Additionally, proper maintenance and component checks will help maintain performance and extend the life of the pump.

Q10: Is there anything else I should know before purchasing a vacuum pump?

A10: Yes! Consider your specific HVAC applications, the size of the systems you typically service, and your personal skill level with handling new equipment. Doing thorough research before making a purchase can lead to a more informed decision and better results on your HVAC projects.

With proper knowledge of size, function, and specifications, selecting the right vacuum pump for HVAC work can empower technicians and enhance system performance!

Concluding Remarks

selecting the right size vacuum pump for HVAC applications is a crucial step in ensuring efficient system performance and longevity. By considering factors such as the type of system, the volume of refrigerant, and the specific requirements of your job, you can make an informed decision that aligns with your needs. Whether you’re a seasoned professional or a budding enthusiast, understanding the intricacies of vacuum pump sizes will enable you to achieve optimal results while minimizing downtime and potential complications. As you move forward, remember that the right tools can make all the difference in delivering quality service and enhancing the reliability of HVAC systems. With the knowledge gained from this guide, you’re now equipped to tackle any vacuum pump selection with confidence. Happy pumping!

One thought on “what size vacuum pump for hvac”