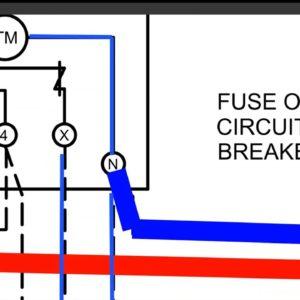

all right so we start by on l1 and l2 on one

and n if you have a 120 volt circuit L to be changed to n in this case we're going to use a

208 circuit that's the one we're gonna see most commonly so we're gonna power up Terminal

one okay there's gonna be a straight shot it's either gonna come from your power on

the breaker or if you have your coil wired through your condensing unit you're gonna take

power from there so wherever we get a dedicated 208 okay as soon as we get power on there it's

gonna send power up to the timer motor okay as soon as this timer motor gets power the time

clock should start advancing so obviously if you have power there and you mark your time clock

and you started doing your troubleshooting you're marked with a sharpie 15 minutes later the

thing hasn't moved there 20 minutes later so it's more noticeable it hasn't moved well you

know the problem right there okay next we have a jumper on terminal 2 to terminal 1 so these are

jumper together okay and then we're sending power up to here and this is a normally open switch

or normally closed switch the arm will go open and close sometimes it's drawn with the contacts

normally closed so come through here we come to 4 okay whenever four has power three will

be normally open so we can see it right here three is normally open this one's drawn

with the arm as well normally you'll see it drawn with the other orientation with the

normally open and normally closed contacts okay so right now three is open okay three

and four will never be closed or open at the same time okay at this point four is

gonna send power down to evaporate fans so now Terminal four is hot and it's obviously

going to be hot all the time as long as we have power coming in so we could draw n here in

the circuit so right now in this setup foreign and/or hot through red and blue so if you test it

across four and n you would get 208 at this point all right at this point Terminal four would send

power to the red side or the l1 leg of the fan motors they're all jumper together as you can see

them they jumper through here okay and then our l2 side is coming from n so we come off of n onto our

red wire so this is like a universal switch that all the manufacturers use you don't need this

specific one for the coil sometimes you want the specific one just because of how it mounts to

the coil but if you're in a pinch a lot of these are universal they use all the same color code

red brown and black so at this point and would send power to terminal C okay so if the coil is

below 35 Fahrenheit this switch here is closed okay if it's above 35 the switch will be open

okay why that's important your fans don't turn on until the coil gets to 35 Fahrenheit okay so

we're below 35 if you go to a call and the coils below 35 it's freezing and the fans aren't turning

on okay you want to check for power between 4 and F first if we don't have power at 4 and F you

start working backwards okay and see why F is not getting power it's probably this switch

has failed okay so on this orientation here our fans working all our Viper fans are working

the switches on the red to black position for an F get power ok now when we go into a defrost the

first thing that's going to happen on a defrost is the normally closed switch tup here they were

talking about this arm is actually going to open so as soon as they defrost starts okay so you

can set those pins use.you it's every six hours we'll say anywhere from half an hour to one hour

usually we'll set it to one hour this arm here is now going to actually open up like this and pin

one is now going to come here and it's gonna close this arm right here so they've drawn this arm

kind of poorly but this arm here is now going to close so we now have power on pin three okay so

this normally open contact now becomes normally closed as soon as we hit that defrost pin on

the timer we're going to come through three all right we're gonna feed the bottom

here or you go right to Terminal three so right now screen and are the only ones that

should be hot okay the fans will no longer be working because we've lost power on four why

we don't want the fans to run during defrost so obvious to use their steam and there's

moisture we don't want that all going on the ceiling so we don't want to push all the steam

and moisture onto the ceiling and then when the cooler freezes then you get all the droplets of

steam on the ceiling and then once they defrost a big ol all over the floor and it might not

seem like much but over time it will collect all right so right now and in three are hot so if we

continue to draw through our n we come through here we're gonna come through our heat or limit

switch so all this switch is just say one of the if anything gets stuck closed and the heaters

always get power we obviously don't want the heaters on when we when we have the compressor

on so we have a heat or limit switch that will open up and I'll turn off the heaters for us this

is going to come up through here and we're gonna feed our h1 so now our h1 is hot and if we look at

our h2 it's wired directly into N and as we know n is our l2 so we always have power on here as long

as we have power up top so now our h1 and h2 the defrost heaters would turn on you frost o'clock

I usually set to one hour okay so what happens now in that one hour is now the coil has gotten

above 35 Fahrenheit so this switch is no longer going to be closed and now we use the second side

of the switch so what happens on this second side of the switch alright so we're gonna come the

defrost termination switch okay once we get to 55 Fahrenheit so that is most likely gonna happen

before one hours up if we have a good coil that's not collecting a lot of ice if we're clocking a

lot of ice and we're going to the full cycle the full one hour that's telling us we probably have

an issue either a drain or something something's freezing up there's too much ice or frost on the

coil could be a TXV adjustment there's all kinds of reasons why so once we get to 55 Fahrenheit

we're gonna close this switch okay so this is our Brown wire Browns going to X okay X is going

up to X on our defrost clock okay so right here we show a load here so this guy right here is

actually a solenoid okay so that's a solenoid okay so because pin three is hot as well still pin

three comes over to here okay so as soon as X gets power and three should be setting power to at all

times this solenoid activates what this solenoid does is it activates a plunger okay as soon as the

plunger goes up and you'll hear it click okay as soon as the plunger goes up and will remove power

from 3 and put it back onto four okay why we want this to happen is what I was talking about earlier

we don't want too much steam in the box so if once we get above 55 that's what we found is the number

of 55 coil temperature not box temperature once we get to that number we're creating a lot of

steam in that box and as soon as we get water droplets on the ceiling and they freeze and then

once we go back into defrost it'll leak all over the floor okay and it adds up over time if you do

it over a couple days or even over a couple even a week is enough for it to be noticeable on the

floor obviously once we have water on the floor it's gonna freeze up we don't have any defrost

elements under the floor so it literally becomes a slip-and-fall hazard as soon as this solenoids

activated we're gonna lose power on three okay and then ii was gonna jumper the power

back up to for this arms gonna be closed again because our solenoid activated and activated

that plunger now that we lost power on three of the solenoids no longer in the circuit and

then four comes back down it's gonna feed this whole circuit again if we have power on terminal

X here okay you can never be in a defrost so if you ever using a defrost clock and as soon as

you put it into defrost right away it's going back into cooling a lot of people think hey the

problems with the defrost clock but in fact you have to come and take a look at this X terminal

okay because as soon as we have power on this X terminal we're gonna have power up here on this

solenoid this is a pretty common problem you're gonna see is sometimes this arm gets stuck up

here and I've seen that happen a lot and I've seen it get stuck both ways actually up and down

okay but when the arm gets stuck up here what happens is it thinks the coils 55 Fahrenheit and

it'll never go into a defrost okay so if you go and you have a clock and even you'll see it on the

true timers they have the green light red light if you go into defrost it goes to red light for 1

second it clicks off the first thing I'm going to is this switch okay if there's power on X we

have power on the solenoid anytime there's power on the solenoid the plunger kicks up it takes

3 out it kicks this arm out it closes this arm right here now we're going to wire we're gonna

wire in a digital thermostat okay so this one's a little bit funny the schematic doesn't really

add up to what they have in the booklet and I'll I'll show you why so the first thing you want to

do is L okay that's gonna go to terminal 1 right here okay we're gonna jumper that in there

we're gonna send a wire from terminal 1 okay now whether you have a 208 or 120 volts unit

okay so we're gonna stick with our 208 we're gonna come from here and we're going right on

end so that means we always have power at the thermostat okay how they've drawn it here is

they want you to take power from from Terminal four okay you can't take power from Terminal

four because as soon as this solenoid they're sorry as soon as the defrost clocks activated

Terminal four will lose power and you'll lose your digital display okay so we're not going

to use this jumper wire so what we're gonna do is from LC we're gonna take this we're gonna go

to terminal 4 okay so that means the only time the actual contacts okay so this side here is for

power and for display the only time the contacts have power is when we're not in a defrost okay

that's important we don't want the compressor running during a defrost obviously it defeats the

purpose okay the compressor will keep running the fans will keep running and the elements will be

on alright your ally know is gonna come here and it's gonna tie into your wire for right here

so you're not going to connect this wire for coming out okay and you're gonna connect this

right into your liquid line solenoid okay so now we have power on here when these terminals

close these terminals can only close way up now now if your in ever in a situation like that where

this switch has failed close if you disconnect this ex terminal the defrost will work but it'll

go for the entire duration so if it's set to 30 minutes or one hour it'll go for that length

so obviously that would be a pretty temporary solution but at least they would get a defrost

and the coil won't be freezing up on them second side is liquid nine solenoid is now gonna get

power off of N and as we know ends always powered up that's your l2 ok it's a straight shot it's

coming from wherever you're coming from either the contactor for the compressor or front separate

circuits it's a straight shot from your power feed you