Welcome to our latest product review, where we’re excited to dive into the world of HVAC efficiency with the “Tools That Can Be Used for HVAC Tools Nitrogen Purging, Nitrogen Purging Tools, Nitrogen Regulators.” As anyone involved in HVAC work knows, having the right tools can make a significant difference—both in the quality of our work and in saving costs down the line.

Having had the chance to put this nitrogen purging set through its paces, we can’t wait to share our firsthand experience with you. This innovative tool not only enhances the performance of our HVAC systems but also plays a crucial role in extending the service life of equipment while reducing potential repair costs.

From its smart design to its robust build, we found features that genuinely stand out. With precise control over nitrogen flow and an ergonomic knob design, using this tool feels intuitive and efficient, allowing us to switch modes effortlessly. Plus, its sturdy all-metal structure assures us that it’s built to last, even with regular use in the field.

So, sit back, and join us as we explore the ins and outs of these nitrogen purging tools, the benefits they bring to our HVAC jobs, and help you decide if they’re the right fit for your toolkit!

Overview of Nitrogen Purging Tools for HVAC Needs

Overview of Nitrogen Purging Tools for HVAC Needs

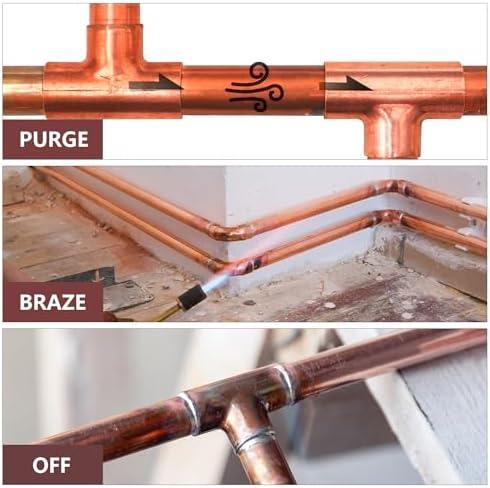

When it comes to enhancing our HVAC systems, employing the right nitrogen purging tools is crucial. These tools facilitate the smooth flow of nitrogen into pipe fittings during both purging and brazing processes, effectively removing refrigerants, moisture, and debris. By doing so, they help prevent oxidation and potential equipment failures, ensuring that our metal pipes remain clean and functional over time. This not only extends the life of our HVAC equipment but also saves us substantial sums on repair costs that could arise from neglecting maintenance.

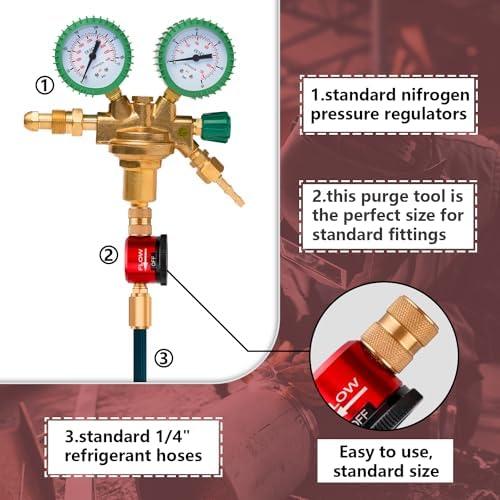

Incorporating durable and sturdy tools with an all-metal structure, we can rely on their wear-resistant capabilities for regular use. Their compact and lightweight design makes them easy to transport in tool bags or pockets, minimizing the worry of damage or breakage. Additionally, the ergonomic knob design enhances comfort during operation. With easily manageable pressure settings—50psi air inlet pressure and a maximum of 200psi—we can achieve stable and precise purging with minimal gas waste. These practical details make our HVAC maintenance tasks smoother and more efficient, ultimately improving the performance of our systems.

Key Features and Benefits of Nitrogen Regulators

Key Features and Benefits of Nitrogen Regulators

One of the standout aspects of nitrogen regulators is their ability to significantly extend the service life of HVAC equipment. They facilitate smooth nitrogen flow into pipe fittings during purging and brazing processes, effectively removing refrigerant, moisture, and debris. This function helps prevent oxidation and potential equipment failure, ensuring that pipes remain clean and functional for longer. By minimizing maintenance costs and reducing the risk of repairs, users can enjoy substantial savings on estimated repair expenses.

In addition to functionality, the regulations we use exhibit a precise control over nitrogen flow, ranging from an air inlet pressure of 50psi to a maximum of 200psi. This level of control leads to more stable purging and welding outcomes, thus reducing gas waste. The all-metal construction guarantees durability and resistance to wear, while the compact design makes it convenient to carry in tool bags or pockets. With an ergonomic knob design for ease of use and access to friendly customer service, this tool provides comfort and peace of mind for users tackling HVAC jobs.

Our Insights on Using Nitrogen Purging Tools Effectively

Using nitrogen purging tools efficiently can significantly enhance our HVAC maintenance efforts. By ensuring that nitrogen flows smoothly into pipe fittings during purging and brazing, we can effectively remove refrigerants, moisture, and debris. This proactive approach prevents oxidation and potential equipment failures, ultimately extending the lifespan of our metal pipes. We’ve found that utilizing these tools not only keeps our systems cleaner but also helps us save on estimated repair costs, enhancing our operational budget.

Another valuable aspect of these purging tools is their precise control over nitrogen flow, which ranges from 50psi to a maximum of 200psi. This feature allows us to achieve more stable and accurate purging and welding effects, minimizing gas wastage. The ergonomic design makes operation a breeze, switching easily between purging, brazing, and closing modes without the hassle of complicated dials or flow indicators. The all-metal construction provides durability while remaining lightweight, making it convenient to store in our tool bags or boxes. Experience the benefits for yourself by checking out this practical solution on Amazon.

Recommendations for Choosing the Right Equipment for Your HVAC Projects

When selecting tools for our HVAC projects, particularly for nitrogen purging, it’s crucial to focus on durability and efficiency. Look for all-metal structures that promise sturdiness and wear-resistance. This ensures that the tools can withstand frequent use without any risk of breakage. It’s also essential to select equipment that offers precise control over nitrogen flow; features like stable pressure regulation (between 50 psi to 200 psi) are vital for achieving optimal purging and brazing results while minimizing gas waste. Tools that allow easy switching between functions such as purge, braze, and close can significantly enhance our workflow and efficiency on the job.

Additionally, considering ergonomics is essential for user comfort during long hours of work. Knob designs that are easy to grip will ease operation and reduce hand fatigue. We should also prioritize tools that are lightweight and compact, as they can easily fit into our tool bags and won’t add unnecessary bulk. Providing us with peace of mind, reliable customer service is a feature we should not overlook—having support in case of any dissatisfaction is reassuring. By focusing on these key aspects, we can ensure our HVAC projects are conducted smoothly and successfully. For a reliable choice, check out our recommended product here.

Customer Reviews Analysis

Customer Reviews Analysis

When it comes to selecting the right tools for HVAC tasks, especially for nitrogen purging, customer feedback can provide valuable insights. As we explore the must-have nitrogen purging tools, we’ve gathered some of the noteworthy sentiments expressed by users. Below, we analyze the common themes from the customer reviews we’ve collected:

| Review Theme | Customer Feedback |

|---|---|

| Ease of Use | Many users highlight how easy it is to control the flow of nitrogen during brazing, allowing for a smooth operation without complications. |

| Build Quality | Several reviews mention the durable and sturdy construction of the tools, comparing them favorably to more expensive brand options. |

| Efficiency | Customers appreciate the efficiency of nitrogen purging compared to compressed air, particularly emphasizing the importance of keeping moisture out of HVAC systems. |

| Affordability | The tools are perceived as a great value for the price, with customers noting that they deliver the same quality as higher-priced products. |

| Recommendations for Use | Users strongly recommend watching fittings and connections to avoid leaks, emphasizing proper handling to ensure the longevity of the tools. |

the feedback indicates that the nitrogen purging tools are a dependable addition to any HVAC professional’s toolkit. Customers consistently express satisfaction with the product’s performance and reliability, making it a worthy investment for both seasoned technicians and newcomers alike. As we continue to enhance our skills and techniques in HVAC, having tools that receive such positive reviews can certainly contribute to our success in the field.

Q&A

Q&A Section

Q1: What is nitrogen purging, and why is it important for HVAC systems?

A1: Nitrogen purging is a process that involves using nitrogen gas to remove moisture, refrigerants, and debris from HVAC systems. This is crucial because moisture and contaminants can lead to oxidation, corrosion, and overall system failure. By ensuring that the pipes and fittings are clean and free from these impurities, we can extend the service life of HVAC equipment and ultimately save costly repairs down the line.

Q2: How do we use the nitrogen purging tools in our installations?

A2: Using nitrogen purging tools is straightforward! We simply connect a standard 1/4″ refrigerant hose to our nitrogen regulator. The tool features three easy-to-switch modes: “purge,” “braze,” and “close.” This eliminates the hassle of having to fiddle with complicated dials, making the job smooth and efficient.

Q3: Can you explain the durability of these tools?

A3: Absolutely! The nitrogen purging tools we’ve reviewed are constructed from a robust all-metal structure. This means they are not only sturdy and wear-resistant but also compact and lightweight, making them easy to store in our tool bags or boxes. This level of durability ensures that we won’t be worrying about wear or breakage during our projects.

Q4: What pressure levels should I be aware of when using the nitrogen purging tools?

A4: Great question! The recommended air inlet pressure for these tools is 50 PSI, with a maximum allowable air inlet pressure of 200 PSI. This range allows for precise control of the nitrogen flow, helping us achieve stable and effective purging and welding results without wasting gas unnecessarily.

Q5: Are these tools compatible with other nitrogen regulators?

A5: Yes, they are! The nitrogen purging tools we’ve discussed are designed to work seamlessly with standard nitrogen pressure regulators. As long as we’re using compatible equipment, we can expect a smooth operation every time.

Q6: What if we experience issues with the nitrogen purging tools?

A6: We truly value our experience and want to ensure satisfaction. That’s why these tools come with friendly customer service. If we have any concerns or dissatisfaction, reaching out for support is easy, and they are ready to assist us promptly.

Q7: How do nitrogen purging tools help in cost savings?

A7: By effectively removing moisture and contaminants from HVAC systems, we can significantly reduce the likelihood of system failures, which often lead to expensive repairs. Keeping our systems clean extends their lifespan and optimizes efficiency, ultimately saving us a fortune in the long run.

Q8: Are there any special maintenance steps we should follow for these tools?

A8: While the tools require minimal maintenance due to their durable design, we should always store them properly and ensure they are kept clean after use. Regular checks for wear and tear will also help ensure they operate effectively whenever we need them.

We hope this Q&A section has clarified any questions we may have about nitrogen purging tools for HVAC! If there’s anything else we’re curious about, feel free to reach out or leave a comment. Happy purging!

Seize the Opportunity

we hope this exploration of essential nitrogen purging tools for HVAC success has provided you with valuable insights into how these products can elevate your work and extend the life of your systems. Investing in high-quality nitrogen purging tools not only enhances performance but also helps prevent costly repairs, ensuring that your HVAC projects are efficient and effective.

With features like an all-metal structure, precise flow control, and an ergonomic design, these tools are a must-have for any HVAC professional or enthusiast looking to provide top-notch service. Let’s keep our equipment in optimal condition and our workspaces organized with reliable and sturdy tools at our side.

If you’re ready to upgrade your toolkit and take advantage of the benefits these nitrogen purging tools offer, don’t hesitate any longer. Check out the product here and gear up for success in your HVAC projects!