Hello, and welcome to the Innovations In Energy Efficiency Webinar Series. This session is entitled, Once Upon a Replacement: Water Heating and HVAC. My name is Mark Reardon and I am a Social Science Analyst in the Affordable Housing Research and Technology Division of the Office of Policy Development and Research. This webinar we'll discuss how long a water heater, space conditioning equipment, or boiler is expected to last and the options available in the market for replacement, and the pros and cons associated with each option.

For each topic replacement and maintenance costs, occupant comfort, and overall energy use will be discussed. Real-world examples will be provided by HUD stakeholders. This session Once Upon a Replacement: Water Heating and HVAC has two parts, the technical portion, and a question and answer portion with all of the presenters. Please utilize the Q&A function within Zoom to submit any questions you may have. At the conclusion of the technical portion of this session, we will address as many of these questions as we can. We encourage everyone to submit questions throughout the presentations. You do not need to wait until the end to submit your questions. As a reminder, all webinars in this webinars series will be recorded and posted to HUD's YouTube channel. The recorded sessions will be posted approximately two weeks after the conclusion of the webinar series. Thank you for joining the Innovations In Energy Efficiency Webinars Series. Enjoy this session. The first speaker of today's technical program is Walt Hunt. Walt is a Senior Research Engineer at the Pacific Northwest National Laboratory where he leads research projects at PNNL's environmental chambers and at PNNL's laboratory homes.

His career and research has focused on characterizing emergent building technologies through laboratory and field studies. Walt, over to you. All right. Hello everyone, thank you for participating in this webinar today. This presentation will serve as an introduction to heat pumps, and provide you a foundational understanding of heat pump technology, and some of the efficiency opportunities that they provide in the residential sector. There are many different types of heat pumps available in the market today. And across the different U.S. climates and different residential applications, there are different heat pump options to consider for energy efficiency. So this slide provides some of the high level characteristics for different types of heat pumps.

So one characteristic is the source of heat. So today, much of our presentation will focus on air source heat pumps, but there are also water source and ground source heat pumps, which can be an efficient option for your residential applications. Next, we have heating performance. So we'll talk about, baseline heating performance versus what the industry is calling cold climate heat pumps. Another characteristic is the backup heating that's used with the heat pump. Whether it's an all electric system using the heat pump with backup electric resistance, or a dual-fuel system using the heat pump and then a backup gas furnace. Also we'll talk about, some of the different uses of heat pumps. Heat pumps are commonly used for space heating and cooling, but heat pumps are also can be used for hot water heating. This image shows the basic schematic of a heat pump and the basic components of the heat pump system.

Each heat pump has two heat exchangers. And you'll see those here on the left and right-hand side of the screen. And the efficiency of a heat pump comes from its ability to move heat between these two heat exchangers. So, on the left-hand side of the screen, heat is absorbed from either air or water or ground source, into a heat exchanger, and then through the refrigeration process, it's relayed over to the other heat exchanger and can then be rejected into the air, water or ground. So this movement of heat from one location to another, between the two heat exchangers allows for part of the efficiency of a heat pump system. In contrast, other heating technologies like a gas furnace or electric furnace, they convert a fuel into heat. A heat pump system is driven by the compressor, and then the refrigeration that flows through these different components and flows through the heat exchangers, allowing for heat to be absorbed in one location, and then rejected in another location.

Heat pumps can provide both space heating and space cooling. So they provide space heating by flowing the heat through one direction and then can reverse cycle and provide the opposite effect. Here is an application for an air-to-air heat pump, providing space heating to a residential application. So in this example, we have a home and we'll say it's winter time and 30 degrees Fahrenheit outside the home. Inside the home, we'll try to maintain the home at 70 degrees Fahrenheit. And so, there is a heat loss effect that will be occurring through the building envelope in this situation. To compensate for that heat loss, we'll need to add heat back into the home. And in this schematic, we're doing that with an air source heat pump. So you'll notice in the photo there, there's two units, an indoor and outdoor unit.

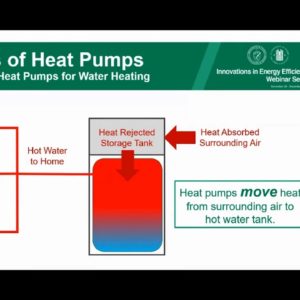

Each of those units would contain a heat exchanger. And so, heat can then be absorbed through the outdoor unit, moved over through the refrigeration process into the indoor unit and then rejected indoors, compensating for that heat loss, and providing space heating to that home. Another application we'll look at is an air-to-water heat pump that can be used for heating domestic hot water. This technology is referred to as a heat pump water heater. So with this type of heat pump, heat would be absorbed by surrounding air and then heat would be rejected into a hot water storage tank. That hot water could then be stored and used throughout the various hot water loads in a home such as, washing machines, sinks, and showers and so forth.

Heat pump water heaters are commonly located in unconditioned parts of the home, such as the garage, or the basement. And so heat pump water heaters would be absorbing that heat from that surrounding air in the garage or basement and transferring that heat into the hot water storage tank. Now we'll talk about, heat pump performance. And we'll look at the baseline heat pump versus a cold climate heat pump. There are two common outdoor temperatures that heat pumps are rated at. 47 degrees Fahrenheit and 17 degrees Fahrenheit. 47 degrees Fahrenheit is the nominal rating point for heat pumps. So a three-time heat pump would be able to provide three times of heating at 47 degrees Fahrenheit.

17 degrees Fahrenheit is the current kind of industry standard for rating heat pumps as well. And so that's why we have these two data points here, but cold climate heat pumps can also go beyond that 17 degrees point down into five degrees Fahrenheit and even lower outdoor temperatures. In our discussion today, when we refer to a baseline heat pump, we're talking about a heat pump that's comparable to a federal minimum efficiency system. So that's the heating output that a system would provide. So, for instance, it may provide two tons of heating at the 47 degrees Fahrenheit and the baseline heat pump, it's heating output would degrade with outdoor temperature down to approximately 60% of its nominal rating point at that 17 degrees Fahrenheit. In contrast, a cold climate heat pump is a system that's designed to maintain that nominal heating output as you drop an outdoor temperature. One of our following presentations, we'll talk a little bit more about cold climate heat pumps and some of the designs that goes into those products. But the takeaway is that both baseline and cold climate heat pumps can be used and contribute to billing efficiency and building decarbonization.

Next we'll compare heat pump performance to gas and electric furnaces. So we just talked a little bit about baseline heat pumps and cold climate heat pumps. And so we're also adding here on this slide, gas furnaces and electric furnaces. So you see the four columns that we have, and the four different categories of heating systems. So, taking the first row, we have a heating output. Gas furnaces and electric furnaces, they provide a constant nominal heating output, regardless of outdoor temperature. Now, we just saw the situation with heat pumps, baseline heat pumps, they lose some heating output with decreasing outdoor temperature. But there's cold climate heat pumps available, which are able to maintain heating output with colder outdoor temperatures. Next, the heating efficiency. So with gas furnaces and electric furnaces, the heating efficiency is one or less than one.

Whereas with heat pump technologies, the efficiency varies with the application, but it can be anywhere from one up to three or greater in COP. The efficiency of a heat pump is generally greater at milder outdoor temperatures and then it does decline with colder outdoor temperatures. But the exact efficiency that heat pump system would provide, you know, varies with the type of heat pump, whether it's cold climate or baseline, the efficiency of the heat pump, and the exact application that you're applying to and the backup heating that's used. With gas and electric furnaces, there's no backup heating that's used for those applications, but with heat pumps, there can be, with baseline systems generally, you would always have a backup heating source, with cold climate heat pumps, again, that would vary with the application. Now moving on to heat pumps and backup heat. So we learned that the heating output of baseline heat pumps decreases with outdoor temperature. That opposite effect is happening with the heating load or the heat loss from a home. As outdoor temperature decreases, the heating load increases.

So at some outdoor temperature, the heating output of a baseline heat pump and the heat load of a residence will intersect. And that point of intersection, that outdoor temperature that they intersect, is referred to as the balance point. So above the balance point, the heat pump only would be able to maintain the heating load at an application at a residence. And below the balance point, the heat pump would need supplemental heat to be able to maintain and match that heating load. In an all electric system where you would have a heat pump plus backup electric resistance heating below the balance point, both the heat pump and the backup electric could operate simultaneously. In contrast with a dual fuel heat pump, you would have the heat pump operating generally above the balance point, and then you would have the gas furnace only operating below the balance point, meeting the load under those colder conditions. Where are heat pumps applicable? To talk about this question, I have a plot here showing the outdoor temperatures for New York City for a typical winter.

So it's broken down into outdoor temperature bins of five degrees Fahrenheit. And so for instance, in a typical year, New York City it will take just a middle temperature there of 30 degrees Fahrenheit, which represents the temperatures from 30 to 35 degrees Fahrenheit. Approximately 18% of the heating hours would be in that outdoor temperature bin of 30 to 35. So you'll notice that even for a colder climate like New York City, that there is a significant amount of heating hours in that milder outdoor temperature range, that 30 to 50 degrees Fahrenheit outdoor temperature range. So these milder heating hours are where heat pumps, even baseline heat pumps can perform very efficiently and effectively in heating a home. At some point, a baseline heat pump would be relying on its backup heat and use that supplemental heat. In contrast, cold climate heat pumps, they can offer even more efficient heating down to even colder outdoor temperatures than baseline heat pumps.

But the idea being that in these milder outdoor temperatures that even make up the bulk of outdoor, of heating hours for colder climates, heat pumps can provide a very efficient space heating option in these conditions. Now some considerations for applying heat pumps. When you're applying a heat pump at a residence, a few things to consider would be whether or not a home has existing ductwork. So there's ducted heat pumps that can integrate with a home's existing ductwork, but if there's not ductwork at a residence, there's also ductless systems that are a great option to integrate with that particular residence.

If there is ductwork at the residence, there might be a need to improve ductwork, whether it be a leaky ductwork, leaking air, or poorly insulated ductwork. In general, heat pumps are sized for a specific application. And they're generally available in smaller nominal sizes compared to gas furnaces. So a gas furnace or an electric furnace may compensate for a leaky ductwork or poorly insulated ductwork, but having good quality ductwork is an important consideration for heat pump systems. Another consideration for applying heat pumps would be the existing fuel infrastructure. So, if a given application has natural gas access, has natural gas piping in place, then it may be a good option to consider dual fuel systems. A dual fuel heat pump, which can provide a heat pump in milder climates, and then rely on the gas backup in colder temperatures. Or if there's existing electrical infrastructure for electric resistance heat, then maybe an all electric system would be a good option to consider.

So in summary, a few takeaways from this part of today's presentation. Heat pumps are also air conditioners, so the addition or replacement of an air conditioner during the cooling season is also an opportunity to consider a heat pump. So a heat pump provides both space cooling and space heating to an application. So whether there's an opportunity to replace the system in cooling season or winter season, both are good opportunities to consider a heat pump for your application.

Next is, that there are heat pumps to consider for different residential applications and climates. There are more heat pump products today in the market than ever. So we've talked about some of these different products, baseline products versus cold climate products, all electric versus dual fuel products. So it can be very application specific, and you should definitely work with a qualified contractor to help determine the best system, consider the best options for your application. But there are definitely heat pump products to consider today for different residential applications. There continues to be product development and studies to determine the most effective and most efficient heat pumps to deploy that will help us continue into the future with more efficient heating systems, but still some great candidates to consider today.

And then lastly, heat pumps can provide space heating and cooling, but there's also heat pumps that can offer efficient heating for our domestic hot water. And so we'll learn about this a little bit more in a later presentation, but there's heat pumps for space heating and cooling, and then heat pumps also that can be used to heat our hot water needs. So with that, I thank you for joining us again for today's presentation, and I'll hand it back over to our moderator to continue.

Thank you, Walter, for the introduction to heat pumps. Next up is Ben Hiller. Ben is a Technical Manager with Northeast Energy Efficiency Partnerships. Ben works across the High Performance Heat Pumps Initiative and provides technical expertise for ongoing activities involving HVAC. The floor is yours, Ben. Thanks Mark. Hi everyone, my name is Ben Hiller and I'm the Technical Manager at Northeast Energy Efficiency Partnerships. We're a regional energy efficiency organization funded in part by DOE, to support state and local energy efficiency, policies and programs. Today, I'm here to talk to you about Electrifying Heating with Cold Climate Air-Source Heat Pumps. So let's jump right into it. Next slide please. So, first of all, why electrify heating? Space heating and water heating account for nearly 2/3 of U.S. home energy use. If our goal is to decarbonize buildings and reduce greenhouse gas emissions, space heating and water heating offer the greatest opportunity. And if you look within those two categories, the vast majority of energy is provided by fossil fuels like natural gas, propane, and oil.

So if we replaced them with electricity, we can not only be more efficient and reduce the overall energy use, but also reduce the use of fossil fuels that create greenhouse gas emissions. Air conditioning is another large energy user, which can also be optimized when we electrify the HVAC system. So when you embark on a heating electrification project, you can save operating expenses, save the environment, and provide a comfortable temperature inside the building year-round. Next slide. Let's look at how electric heat pumps are more efficient than any other type of heating.

Burning fossil fuel is always less than 100% efficient. Electric resistance heat is 100% efficient because all the energy from electricity is converted into useful heat. And heat pumps, because they absorb heat from outside and release it inside, are always more than 100% efficient. Even when the temperature is five degrees outside, they can be over 175% efficient. Now, how that translates to operating expenses, heat pumps costs less to operate than oil, propane, and electric resistance heat, and can be cheaper than natural gas depending on utility rates in your area. Next slide. So what's the challenge for heat pumps in cold climates? It's the air-source heat pumps have to work harder in colder outdoor temperatures. In the past, heat pumps could not operate in the coldest temperatures and needed auxiliary heat. Here you can see the IECC climate zones with some rules of thumb for heating capacity in each zone. In Florida, you would only need 30 to 35 BTUs per square foot. But in Maine you would need 50 to 60 BTUs per square foot. So how can cold climate heat pumps provide so much capacity with very cold outside air? Next slide.

The answer is flash injection technology. The problem is that if a compressor spins too fast, it overheats from friction. So you inject a liquid vapor refrigerant mixture into the compressor to cool it down and allow it to spin faster. The faster compressor increases refrigerant pressure and temperature, and the compressor sends hot refrigerant to the indoor units. Let's see what that does for cold climate heat pumps. Next slide please. As an example of how one manufacturer categorizes their product lines, a good heat pump has 60% heating capacity at -4 degrees, a better heat pump has 78% capacity, at -13 degrees, and the best heat pump has 70% capacity at -22 degrees. So no matter where you are in the country, you can design an air source heat pump system for your coldest winters. Next slide. Let's talk about how to size the system. First you need to do a load calculation where you measure the room and window dimensions and make a list of the insulation values in the attics, walls, and basements, along with the window types and direction.

In new construction, the cooling load is often higher. In older homes, the heating load is often higher. Ensure that you have capacity to meet the highest load. This is why it's so important to weatherize and insulate before you design your system. If you have an old leaky house and you're able to improve the building envelope, you can reduce the heating load. Next, you select the design temperature. For example, five degrees in Boston. ASHRAE weather data shows 17.3 hours a year at or below five degrees. And all that will happen during those hours is the temperature will drop a few degrees below set point. Engineers are typically very conservative and will often design for zero degrees in Boston. If you're also conservative with your load calculations, you can see how that would lead to a bigger system than you really need. Lastly, you should use manufacturer software to select units to meet the heating and cooling loads. Use cold climate units if they are the best match. Let's look at some examples of replacing the system in a house. Next slide. If you have a ducted furnace and central AC system, you can replace it with a ducted heat pump.

Size the heat pump for the full heating load or use the furnace for auxiliary heat. Fossil fuel auxiliary heat is called dual fuel or hybrid heat. Hybrid sounds nice, but remember, it's always more efficient to use a heat pump than burn fossil fuel. Existing furnace-only systems have smaller ducts. Replacing with a heat pump will likely require larger ducts for air conditioning. If ducting is too much trouble, or you just don't want ducts at all, you can get a ductless system. Next slide. How's this with baseboard heat or radiators are good candidates for ductless heat pumps. You can have a single zone system with one indoor unit matched to one outdoor unit, or a multi zone system with multiple indoor units connected to one outdoor unit. Each indoor unit can be sized to serve multiple adjacent rooms called a zone. As an example of where to fit the units, you could replace your radiators with floor-standing ductless units. Next slide. There are many indoor unit types to choose from.

A one-way cassette is recessed in the ceiling and typically goes against a wall and blows into the room. A four-way cassette goes in the middle of the ceiling and blows in all directions. Ceiling suspended is available when you can't recess the unit in the ceiling, wall mounted is probably the most common and goes high up on a wall, and floor standing as we saw is a good replacement for a radiator. Next slide. You can also have ducted indoor units where only the vents are visible in the space.

A concealed ceiling ducted unit is perfect to serve two or three bedrooms as shown here, and we saw that a vertical ducted unit can replace your existing furnace and AC in the basement or attic. Next slide. For multifamily housing, you have some interesting choices. You can do a single zone unit for each suite, which is easy for individual ownership and servicing where you can have a VRF system, which stands for variable refrigerant flow, and uses a branch box in between the outdoor and indoor units.

VRF systems can be about 10% more efficient because they use fewer larger units and they typically have the best cold climate performance. They have a much smaller footprint on the roof that leaves room for solar panels, and there are fewer units to power, pipe, and maintain. One great benefit of VRF is that it can do heat recovery between rooms. So if you have one room that needs heating, and one room that needs cooling, they can share heat between each other, and reduce the load on the outdoor unit. VRF also has longer piping capabilities, which is helpful for larger buildings. Next slide. Packaged terminal air conditioners are common in multifamily high-rises particularly in cities like New York, and provide a great opportunity to replace with packaged terminal heat pumps. Single package vertical units are also commonly placed in closets and ducted into the space, which can be replaced with single package vertical heat pumps. Next slide. To learn more about all of these units, visit the NEEP Cold Climate Air-Source Heat Pump List. It's a great repository of performance data for units that meet our cold climate specification, which is used by energy efficiency program administrators as minimum requirements for rebates.

One example requirement is that units must be at least 175% efficient at five degrees outside. Single zone and multi zone ducted and ductless units are available now, and VRF packaged terminal heat pumps and single package vertical heat pumps are coming soon. So remember, heat pumps are always more efficient than burning fossil fuels, and cold climate models are available to meet your heating load at your design temperature.

Next slide. So with that, thank you. I hope you enjoyed this presentation. Please reach out to me if you have any questions at all, I wanna say thank you to DXS New England for providing some of the graphics, and thank you to DOE and HUD, and the whole team for putting together this webinar. Mark, back to you. Thank you, Ben, for the presentation on cold climate heat pumps.

Next up is Geoff Wickes. Geoff is a Senior Product Manager with Northwest Energy Efficiency Alliance. Geoff works closely with utilities and trade stakeholders to help identify and prove out innovative energy efficient technologies to transform markets. Take it away, Geoff. Mark, thank you for the introduction. We've got a lot to cover. We're gonna be talking about water heating in all kinds of applications. So I'm gonna jump right into it. So, what is this conversation gonna be about this morning? We'll be talking about water heating, how the heat pumps work, and what building types and locations are they often found in. What are some of the solutions? We're going to cover a brief study, a case study that we just recently finished in Seattle, some challenges and some do's and don'ts. A little bit about me, I work in the Emerging Technology area for NEEA, the Northwest Energy Efficiency Alliance. We're funded by 140 utilities here in Oregon, Washington, Idaho, and Montana. We're focused on energy efficiency. And my target area is, connected buildings and efficient water heating.

So we work with the market, and we work through market channels to affect change. So why are we focusing on water heating? Water heating makes up about 18% of the total load in any building. Whether that's a commercial building for multifamily or in single-family. This is based on a lot of our studies, and what DOE and Energy Star had been saying. So how do heat pump water heaters work? Works like water pumps, they don't create water. I don't know if anybody has ever made water, but if you do that, it's very time consuming and very energy intensive. We're just transferring heat in this particular case. Like these pumps here, they're moving water from one rice pond to another. What a heat pump water heater does is they collect air from the outside surrounding area, and they put it in through a system pulled in through their evaporator coil, and it exhausts out the extracted cold, dry air.

And then it gets put into a compressor and increases the temperature much like your own refrigerator does by extracting the heat out of the inside, and putting the cold into the refrigerator or into the freezer compartment. It that gets that refrigeration is pumped down into the condensing coil, which is located in this particular case, in the bottom of this tank, and it heats the water from below, and that creates a full tank of hot water. This process is not new. And as I mentioned, refrigerators, freezers, air conditioning units, whether it's in your house or in your car, all works on the same principle.

It's a phase change process of compression in evaporation. So where are these often found? So in single-family residences, we find them in garages, and in basements. This is from one of our studies, and so roughly, 52% of all water heaters are found in either garages or basements. And the rest are found in the main part of the house or in other obscure locations. And we'll talk a little bit more about this. So why does that matter? Well, in garages and basements, it harvests the heat or energy from the surrounding area. In a garage, really not that important, and in most basements, it's not that important, plus it's directly coupled to a great energy source, which is the earth. So the earth radiates energy through the floor or the walls, somewhere between 47 and 55 degrees and even warmer in some locations. Standard water heaters are replaced like for like in most instances now. So, if you have gas, it would be replaced with a gas. And what we're proposing in like for like for electric, we're proposing that you put a heat pump water heater in those locations. It's an easy transition, no additional wiring, you do have some things to consider and we'll talk a little bit more about that.

So, what is needed for these technologies? 750 cubic feet of space that it needs to harvest the heat from. So you'd never want to put this in a very small, tight closet that didn't have any breathing room. There are solutions around that, and we'll talk through that. You need a place to put the condensation. Because as you harvest that heat from the surrounding area, especially in the winter, it will produce a modest amount of condensation, and it needs to be expressed and disposed of. But this is not toxic, it's not like a gas fired furnace or water heater, where it actually produces sulfuric acid. This is completely safe and can be dumped right into the drain with no treatment necessary. You need the right amount of power to do this. And most electric water heaters now are supplied by two 40 volt, 30 Amps, so you'd just use the same one. Now there are heat pump water heaters that do use less power and or less voltage. So the new ones coming out are 120 volts, and they run on a shared circuit.

There are also two 40, 15 Amp products that can be used if you've got panel constraints. One of the key areas that we'd like to focus on is, the people who should be buying this, are the people who need it the most, and people who wanna save money on their water heating. And then additionally, people who want to make a difference. And these, as you can see by these two different images here, the one on the right is from the Northwest, the one on the left is in the Northeast, and it is just a typical housing stock.

No special attributes about it. So they go in almost any place. The other place they go into, actually let me back up again. Well, I wanted to spend a little more time looking at the best locations. So, we've got 10 possible locations within most homes. And you'd be surprised to see that when you look at where they work and where they don't work, about 60% of them fit into places where they're already there.

So that's not a problem. The other 40%, there's a little more challenging in the attics, dugout crawl spaces or tight closets. And then the under-counter or lowboy under a sink is not a place you can put these. So you would have to relocate those. Now, there are some solutions for doing that, and we'll talk through those. So, right now the current products available are made by all three of the major manufacturers, and that accounts for roughly 95% of the total market share of unitary residential tanks that come in 40, 50, 65, and 80 gallon, and they all carry a 10 year warranty if they are a heat pump listed on our qualified products list, and all the major brands have those.

It's a proven technology, it's been around for more than 30 years, it's relatively easy to install. A few more additional things to consider, one as I mentioned is, the condensate management, and then the other is, they do have an air filter that does need to be changed or serviced every so often. And then the newer products, all carry demand response technologies. One of the other elements that is very important compared to the older versions of this, is they're much quieter than they used to be. The current state-of-the-art product is running about 49 DB, and they're heading to even quieter, quieter levels. The other application that we often look at is in multifamily. And there are three different building types I'd like you to consider. There's the low rise, mid rise, and then the high rise. This market can all be met with either unitary or split systems, both single and multiple heat pumps, and multiple storage techniques.

And we'll walk through those. But as you can see, they do work in many different places. Here's the breakdown of where the water heaters are located by building type. So as you can see, the vast majority of them are all electric in-unit applications. So these are in low rises, one to three stories, there are some in mid rises, and then you're starting to see some central and or gas fired boilers. So the large scale units, we're gonna talk a little bit more about, but let's take a quick diversion into the in-unit and the outside of unit.

So in-unit, you'll find these located in small closets or adjacent to other living spaces. These are the ones you need to be a little bit cautious on, so that you're not blowing cold air into a living space that would be impacted by it, or they don't have sufficient make-up air. There are some solutions here and you can duct both in and out of a tight closet, but you never want to be ducting just out of the water heater, outside the envelope. You always want to be either in and out of the envelope, or within the envelope. We've had plenty of situations where people will say, you know, actually, I like that cold air to be dropped off in our kitchen, where we generate a lot more heat, and I wanna be pulling the air from an area that's always a little warm. So you can work with the customers or the situation to work on the best solution. The other application are often found, especially in warmer climates, on patio, or what we refer to as doghouse locations. So it's located on a patio or a little closet off of a deck, and those you can generally breathe in and out of either ducting or with a grilled door, and it works just fine.

If a water heater is already located out there, you're not gonna find that there's much of a problem with freezing. The biggest worry actually would be the freezing of the pipes. But if the situation is still not working right, we do have solutions. And this is what we call the split system. The split system allows you to put the outside evaporator outside of the unit, pipe the hot and cold either refrigerant lines or water lines into a standard tank inside a location. A good example of this might be if you had a water heater underneath a stairwell or in a very small closet, and you just wanted to have the water heater left there, but you wanted to harvest the heat from the surrounding area.

Lots of more brands coming and we're finding products from Asia and Europe are getting domesticated here and you'll see them on the marketplace more often. The next area I wanna talk about are, what we refer to as large commercial systems. This happens to be a building in Seattle. It's a built-up system and I'll explain the difference here shortly about that. But this has the heat pump engine, the storage for made water, and then the recirculation, it may also have a mixing valve controls, and several other automations. But it's just like a unitary system. It pulls air in from a location and then dumps out cold air. In this particular case, it's located in a basement. Inside of a parking garage, the average temperature inside that parking garage is about 52 degrees, and it cools the area around where cars are parked, not an impact to the people living in it.

It also has… So over here is the engine, which is just like the unitary. There's storage located in one of these tanks, and then there's a maintenance tank for maintaining the recirculation loops, and then there's a whole bunch of valves and controls. So what I wanna show you next is, how we took this concept, and we worked with the marketplace, and it was pre-built outside of a building, and then brought in and hoisted onto an existing structure. So this is what we refer to as a product on a skid. This is actually being assembled in a factory in North Dakota. It's a combination of a bunch of storage tanks, a header pipe, valve controls, and then it's a Mitsubishi QAHV heat pump, which is being integrated into this system.

It will come as a system and it arrived in Seattle on a truck in its own house, and then it was lifted up onto the building, and it was put in place for the 100 units dwelling there in less than four hours. It was demand response ready, and it has all of the evaluation measurement and verification on board, as well as monitoring the system to make sure it's working.

So, if you're a building manager, you can monitor this remotely. It communicates with you via either text or an onscreen element. So you might ask, what are some of the challenges with heat pump water heaters both in residential, single-family or multifamily. So single-family, first cost is a bit more right now, although we are starting to see that price come down. They need sufficient make-up air and they need a place to dump the condensate. And as I said, this is not toxic, but you do need to get rid of it. You also have some localized cooling while running.

In my particular case, mine runs about two to four hours per day, and it's localized in our utility closet, which we harvest some of the heat from our inverter, as well as our heat pump dryer. It makes a little bit more noise than the perfect appliance of the electric water heater, which is just a silent device that works quietly in the background, and spends a lot of money.

Plumbers are not that familiar with it. So there will be an education to bring the plumbers and the trades online. Multifamily, it's a little bit different. There are challenging installs for both interior units and large scale. The cost to convert to a central system can be a bit higher and it does require more water storage because these heat pumps will operate for a longer period of time, build a tank of water, and then they'll be able to use that throughout the whole day, or through large demand response periods. There will be some challenges within the mechanical room to do these conversions, especially when going gas to electric. So you need a bigger mechanical room. Designers, engineers, and installers are not that familiar and property managers generally don't know anything about it. So one of the burning questions that a lot of people have is, so where does all this heat come from? When NEEA commissioned to study with Pacific Northwest National Labs, where we did an interactive study. Where we had two identical lab homes, and we moved electric resistance, and heat pumped water heaters in the exact location using the exact same heating systems.

And what we found was, in the winter, there was a little penalty, very modest. And during the spring and fall, no penalty at all. And in the summer, it actually provided beneficial cooling. This study was done in Richland, Washington and it's available, there's a link down there on the bottom. We've also been studying what customer satisfaction has been over the last five years. And we are seeing north of 93% customer satisfaction with all heat pump water heater installations. Some of the additional benefits we often look at is, we're spending a whole lot less on heating water, 1/3 to 1/4 of what electric resistance water heaters costs. They have a longer warranty. Typical warranty for a gas or electric water heater is six years.

We're now insisting on 10 years and the industry is compliant and we have no reason to believe that they don't last that long. It reduces your carbon footprint because you're not making heat, you're just transferring heat. It also reduces circuit loads because a heat pump water heater operates at a much lower wattage than a traditional electric resistance element. It also has demand response capabilities. So you can shift that load around and integrate more renewables. It also enables some jurisdictions to switch from a fossil burning fuel to an electric water heating based. So what's going on in the future? We're seeing lower first cost come down. A federal standard is gonna be in the wings here soon. We're gonna see continued innovation. This particular image here on the right is actually coming from Italy and it's going to be made here in America. It's looking much more stylish. Yeah, whereas the old traditional tank water heater is kind of dull.

They use a lower global warming potential products. So you're gonna start seeing refrigerants that are more environmentally friendly. Plumbers are gaining a clearer understanding and they're seeing the value in it. Sleeker designs, they're looking at complete system solutions. They're not just looking at different elements in the commercial space. So they'll look at an engine storage, maintenance valves, and controls. And as I've said, this technology will enable more renewables on the grid so that you can better deal with the fluctuation of grid costs. So, I wanna walk you through a little bit of what's going on in the commercial space. Current business as usual, highly engineered. This is where we're heading now where it comes as a kit or a package, and in the future, it will come on a skid.

So this is truly innovation. It's gonna come either in a container, on a skid, or in a what we would refer to as a kit like Lego or Ikea. So it could easily be put together. That's about all I've got for you today. I'm gonna leave it up for questions and discussion later. There are somme links here. And here's how to get a hold of me. Thank you, Geoff, for the presentation on heat pump water heaters. Next up is Thurston Stimage. Thurston is a Director of Building Operations for the Chicago Housing Authority known as CHA. Thurston has over 20 years of experience as an operating engineer and oversees overall management of preventative maintenance, energy efficiency, and HVAC system replacement programs for building across the CHA portfolio. He has played a key role in establishing performance standards for CHAs Critical Building Systems, and has demonstrated skills and team building through successful partnerships to obtain outside funding for energy efficiency incentives.

Over to you, Thurston. Thanks for the introduction Mark. As Mark said, my name is Thurston Stimage. I'm the Director of Building Operations for the Chicago Housing Authority. Next slide please. Chicago Housing Authority. Quick overview of the Chicago Housing Authority. Chicago Housing Authority provides housing to 25,000 households. High rise buildings are all senior apartments, studio and one-bedroom. Town homes and or mid rise buildings provide housing for families on plan developments. CHA also has scattered sites that provide homes for families across Chicago. Heat Pump Design. The CHA designed the heat pump system to provide heating and cooling. It requires minimal space. It has a redundant backup boiler system to support the heating side, distribution systems have been replaced, and a refrigerant leak detection device have been added to the VRF system to help control any refrigerant leaks.

Let's go over some of these points. Providing heating and cooling. The heat pump systems allow the units and the resident to have heating and cooling at any desired time. These units are very small and take up very little space. The redundant backup water system is utilized to primarily support community spaces and to also add supported heating needs to units on 20 below and 25 below degree days. The distribution system, which is one duct defuser from the heat pump, is also been replaced in unit. And as I mentioned, the leak detection system that was added to the VRF, it helps monitor and control any refrigerant leaks that may occur throughout the system. Heat Pump System. Variable Refrigerant Flow system, the VRF system. Heat pumps are sourced by refrigerant through VRF systems that provide heating and cooling.

Refrigerant lines are connected to fan coil units and conditioned air is distributed to the living room and bedrooms through a duct defuser. Each floor is zoned. Fannie Emanual has four zones with separate risers, isolation valves, and a refrigerant leak detection system as I mentioned several times earlier. The redundant boiler system is installed as a backup for the heating portion of the system. As I mentioned, this is primarily used for common areas, but it also can be utilized in unit if in fact the VRF system does not provide enough heat on 20 below or 25 below days where most systems are challenged and you need a little bit extra support on your heating systems.

These boilers are central to the building. All risers and piping to the boilers were replaced as well. Primarily a fairly new redundant system has been installed as well with a Variable Refrigerant Flow system at this site. Here's an illustration of the in-unit heat pump. This is a (inaudible) style heat pump that's used in all applications. As you can see in the picture on the left of the window AC unit is the end result. Is the installed heat pump system.

Heat pumps were installed after our initial renovation and a full gut rehab to the building at Fannie Emanual. Next slide. In the illustrations you see here is a finished product. These are units that have been finished at the Fannie Emanual senior high rise building. As you can see in the circled area is a heat pump system, it's a heat pump unit. These units are controlled by the residents. As a result of installing the heat pumps system into our building, we have learned some lessons. We have some pros and cons that we would like to share with this group. One of them is, we were able to provide individual control for each resident in unit, allowing them to control the comfort of their unit through a thermostat that's connected to the heat pump system. Each system as you've seen in our last slide is compact and very small and neatly installed into the unit.

Heat pumps systems also have a low rate of energy loss. We've experienced the reward to that. One of the other lessons we also learned is the cons. As I mentioned throughout the presentation, we have installed leak detection monitoring devices throughout the building to help control any refrigerant leaks that may occur on the systems. They do occur. And because this is a new system that the CHA has been using, it has been some maintenance, some excessive maintenance, or let's say more maintenance to kinda work out the kinks and control the refrigerant leaks. But we're moving towards successfully doing that. And because of that, that may increase the repair cost. But as I mentioned, all the work that we're doing now is to rectify this issue, and hopefully control it better and bring down the cost.

So in my final notes, I would like to just say, consider using air-source heat pumps in the future. That concludes my presentation today. Thank you all for joining us back at you, Mark. Okay, wonderful. So again, thank you, Walter, Ben, Geoff, Thurston. That was an excellent presentation. I think we all benefited from some of the real world examples that you provided. Those are always helpful. For those of you that may have come in late, just a quick reminder, this webinar will be, obviously it's being recorded, it will be hosted to HUD's YouTube page in about, maybe two or three weeks. So, check back in for resources. There's a lot of links, a lot of interesting projects going on that were mentioned in these presentations. And I'm gonna get right to it. It looks like we have quite a few questions. So I'm going to tackle the ones that we have in the chat first, and then we'll get to a couple others, and I have written down questions just in case, but our panelists feel free to unmute yourselves and answer as you wish, or I will individually pick on you.

So, let's see. First question. How is heat absorb outdoors if it's 30 degrees outside? Mark, I know the answer to this one. All right. So although it feels cold to us, the air has heat all the way down to absolute zero, which is -273.15 degrees Fahrenheit. So, all you have to do is design your refrigeration cycle to be able to absorb that heat and then release it inside. So it works. Very cool. Very cool. Anybody have anything else to add to that? I think that was a pretty comprehensive answer. I was just talking to somebody who is using underground natural ducts to heat their home. I think it's called an earth ship and they were telling us, you know, that the constant temperature below is about 55 degrees, which I had no idea. So they're able to get cool air in Arizona apparently.

Okay. So second question. Are there any heat pump replacements, many split, et cetera, for a 277 volt PTAC? I would say yes to that one as well. Definitely those products are available as a PTAC size factor itself, as a heat pump, or as a split system where the indoor unit would take the place of that PTAC and there would be an outdoor unit somewhere outdoors. You know, and just to follow up on that, what's the best way to kind of figure out what your replacement should be? Is there a step-by-step, you know, if this is what you have, maybe look at these type of things, or how do people sort of troubleshoot what they're going to replace it with? Definitely take a holistic approach, and look at what's available.

I would consider the energy efficiency of the entire system. And if you can't do that, then you can just chip away in little places. You know, if you have an existing furnace, and because that ductwork is smaller and would need to be up-sized for air conditioning, you could just leave that furnace alone, and in one room, add a mini-split. And then, you know, use that for as long as possible and use the furnace if you have to. So you can either tackle the whole challenge at once, or you can tackle it in small pieces. Mark, this is Geoff with NEEA. I'd also like Ben to talk a little bit about, especially about PTACs and he's definitely the expert here, on the new style of PTAC, which are the inverter driven ones, rather than the standard ones. That's a substantial way of improving your efficiency for not much incremental cost. Yeah, thanks Geoff. So, historically that form factor has been very difficult and only recently in the last couple of years, have you seen the inverter compressor, which just simply means variable speed compressor, which allows you to have that cold climate performance in that small form factor.

So, these are just coming on the market now, they are available today, you kind of have to have to learn about them and then go out of your way to look for them 'cause they're new. But that is an excellent option. If you have an existing PTAC unit, you can replace it with a packaged terminal heat pump with the cold climate performance.

So, I know as Thurston was saying, they did have backup heat in the future and arguably today, you could design a system that wouldn't even need backup heat, depending on your cold climate design temperature. And Ben, I think it might be helpful for the audience to understand some of the other benefits of these new inverter driven PTACs as far as performance and how they interact with the human audience. Yeah, that's a great question. You're setting me up really well here. So, a typical complaint about ductless systems is that the temperature coming out of them is not quite as hot as you're used to. What you might be used to in your house is feeling cold and then your nice gas furnace kicking on and getting a nice blast of hot air.

What the inverter compressor allows you to do is very tightly maintain your set point. So if you wanna set your thermostat to 68 degrees or 70 degrees, or even a little higher, that system will maintain that temperature the whole time. You don't have huge temperature swings, like you might be used to feeling a little cold, and then the system coming back on, so that's kinda two birds with one stone there.

I would say if that's a complaint, that the system doesn't blast out hot air quite as hot as a furnace, you know, turn up your set point a little bit and you will just leave the system run with that again, inverter, variable speed compressor, it gives a much more level set point for temperature control in your space. Sorry, Mark, you're muted. Yep. You know what? I tried to behave and mute myself and unmute myself, it's not gonna work, I'm just gonna leave my microphone on so all of you can enjoy my commentary.

Anyway, thank you, Ben. That was quite informative. And Geoff, thanks for the tee up there. I do like the idea of the systematic approach to this. And looking at it as in the whole versus just part, looking at exploring both of those options, which I found particularly interesting in Geoff's presentation. But onto the third one. Is heat pump cooling performance related to outdoor temperature? Yes, yes as well.

These are all yeses, I like this. So, just like the heating performance is related to the outdoor temperature and it degrades as the temperature gets colder because the heat pump has to work harder. In cooling it's also harder if the heat pump is rejecting that heat to hotter and hotter temperatures. So there are, you know, ambient limits. Obviously there are systems to work in high ambient temperatures. Just as today we were speaking about cold climates, you can check your rating for your system and ensure that if you're in Dubai, that, you know, your system will work. Interestingly, this is a fun fact. That a heat pump is a little bit more efficient at heating than it is at cooling. Because the heat of compression from the compressor is beneficial in heating mode. You actually like that heat. But in cooling mode, the very first thing you have to do is reject that heat outside in the condenser.

So overall, you are a little bit more efficient as a heat pump than as an air conditioning. Now, one thing I'll add to Ben's comments there is for different products in the market, there's industry ratings. So for residential unitary systems, there's SEER is the cooling efficiency metric, HSPF is a heating efficiency metric. So if you're considering different products, you can use those industry metrics, which are general good guidance for higher efficiency products compared to baseline products.

Now, let me follow up on your response there. Are these industry, like you said, are they industry wide or do they vary? So it varies by product type. So, for residential split systems, for like a single-family home, the metrics will be SEER and HSPF, for package terminal heat pumps for instance, I think those are generally rated based on COP. So there is a little bit of difference between product types, some on what that efficiency metric will be. But if you're working with, you know, a good quality contractor, they'll be able to, you know, show you those ratings, and give you some insights, and if you're comparing products, you'll be able to see those industry ratings, which are available for all products, although they may be slightly different between technology categories.

Great. Thanks Walt, Walt, one question, this is Geoff again, with NEEA. I think Ben is working with NEEA on some new standards for cold climate heat pumps, and it's worth noting that, that new standard will be probably more universal and more meaningful across the nation, even around the world. So, Ben, you might wanna talk about that. Sure, absolutely. So that's going back to speaking about the products which are just new, emerging on the market right now, packaged terminal heat pumps, and also single package, vertical heat pumps, which go in a closet, and then are ducted into the space, I believe we had a picture of that. So, because they are smaller and the challenge has always been that small form factor, they are slightly less efficient than the other ductless heat pumps that are currently on the NEEP list.

So just as an example, our current spec for the mini-splits and multi-splits, what you would call the ductless heat pumps, is the COP of 1.75, which in layman's terms means, 175% efficient at five degrees, and for our new cold climate standard for the packaged terminal heat pumps, and the single package vertical heat pumps it's going to be 1.5. So still, 150% efficient at five degrees. So, I'm very happy to be able to get out this information today. If you do some Googling yourself, you'll immediately see people talking about the efficiency degrading for air-source heat pumps at cold temperatures, but it's just outdated information and it's true. Those units are still on the market, but also the new units are on the market. So it's up to you to be able to do your research and I hope there's some people out there today learning that it is possible to buy some of these cold climate air-source heat pumps.

Great. Thanks Ben. So, heat pumps available for everybody in any temperature basically, standards to go by, and lots of comparison methods and tools. It takes a little bit of research, but the good news is, there's an option for everyone out there. Which brings me to our next question. If I live in a very cold climate, can I use my existing furnace as a backup heat and add on an ASHP as my primary heating and cooling needs? Yes, absolutely.

So, you can use the furnace as it is, don't even touch the furnace and simply add in some ductless mini-splits around your house, or even with short duct runs, as we saw, for the aesthetics, if you really don't wanna have the units in the space or, you know, you're fortunate enough, or maybe you're redoing your roof then at the same time, you can add in a heat pump up there, ducted into some bedrooms. So that's one way to go. Or there is a product where you can put a coil on top of your furnace, a heat pump coil on top of your furnace, you do have to up-size the ducts, but absolutely, either way, you can keep your existing furnace if you'd like.

And the followup to that was, is it cost justified? To the planet? No way. (all laughing) Is the (inaudible) talking the cost, or are we talking the cost of the system? I would look at both options and I would try to work with the contractor who is able to offer you a system that can completely heat your home with the heat pump. There are contractors who simply don't carry the equipment and will tell you that it can't be done. And it is true from their perspective.

They don't have the equipment for it. So, if your mission is to electrify your house and your heating, if your mission is to electrify your heating, there is a contractor out there for you. Awesome. Alright, so, oh, sorry, did I hear somebody speak up? Feel free. Okay, let's move on then. So, anybody wanna talk about the problems? Or if there are any problems associated with ductless heat pumps. I got a good one for this one. Filter changing. So, filter maintenance, if you have a central air handler, you have one big bank of filters, and your maintenance is you ignore it forever and you just forget they exist. No, I'm just kidding. Hopefully you replace your filters. And this is an actual issue, particularly in multifamily housing. I mean, who is maintaining the filters? You always wanna make sure that, you have good filter maintenance. So, if you have ductless heat pumps and there are units spread around, typically if the unit is in the space, it will be a washable filter, and you would either need to communicate to the tenant or to your maintenance staff to wash that filter.

And if the unit is in the ceiling or in a closet, communicate to maintenance staff to replace that filter. And just to tag on to Ben's good thoughts there, ductless units, you know, are like traditional central systems and if they, you know, connect generally to an outdoor unit or refrigerant piping that would also have a condensate line that would run out of them. So, your contractor would work with you on getting those things considered, and how to go about that for a particular application. But, you know, ductless units, although they hang on the interior wall of the space, they still have that kind of behind the scenes electrical or refrigerant piping and so forth that's part of the part of the overall system.

Great. Thanks guys. Next question. Is there a climate that's too cold for cold climate heat pumps? Yes, there is. If your design temperature is just simply too low. There is a solution though, this is great. You can actually install the outdoor unit in a penthouse and then have a separate heater to actually heat your outdoor units. So, if you wanna make it work, there is a way. It is possible. And we haven't brought up ground source or water source yet in the Q&A, but I would also say that, as far as heat pumps are concerned, absolutely you could use ground source heat pumps.

And as you mentioned, Mark, taking advantage of that much more consistent ground temperature during the winter. If you imagine the struggle for a heat pump when it's very cold outside, and you're trying to absorb heat from increasingly cold air, much easier to absorb heat from the relatively constant ground. And I think it's also worth noting, it's good to understand with how long is it, and how cold is it, for how many bin hours per year? So if you're hitting those low temperatures for six or eight hours during a year, well, maybe you need to just have a little electric resistance to get you through that, but the vast majority of the time you're using a heat pump, you're gonna be far better ahead.

Especially if you look at the overall implications of having a fossil system in conjunction with it. You could also put in a fossil, you know, use your fossil system to solve that for those short periods as well. I thought I heard someone else chime in, but if not, we can move on. I like your approach though Ben. It's like, well, yes, of course there is, and if you wait, you know, we have 30 units left for $999. You too can get. Call the number on the bottom of your screen. I like that. So guys, eighth question. What do I have to know when switching from electric water heater to heat pump water heater? So I can address that. I think I mentioned in the deck, you got to have sufficient make-up area. So you need about 750 cubic feet of air that that water heater needs to interact with. You don't want that in a constricted space, you don't want a super cool that space, 'cause just imagine if you had a refrigerator and there was no place for that warm air to go out, your refrigerator would basically choke itself to death and it would be warm on the inside and warm on the outside.

So, you do need sufficient space, and then you need a place to get rid of this modest amount of condensate. And that condensate doesn't happen year-round, and it's not excessive amounts, it's not gallons and gallons a day. It's more like, two quarts a day in the heat of the summer when there's a lot of moisture in the air, but in the winter, especially in Northern climates, you'll find very little coming off of that. So you do need the make-up air, and then if you do have a ducting situation, you don't wanna be blowing that cold air into a space where somebody might be impacted by it.

For example, I wouldn't put it in the bedroom closet of a nursery for a young child blowing it right on onto their crib, bad idea. Putting it into your kitchen or putting into a hallway, or putting it into your laundry room, or especially in your basement that's got lots of other utility activities going on, perfectly great location. Or here in the Northwest for example, we see them a lot in garages, and we actually, this is a personal experience, we would roll down our windows, drive our car into the garage, and because of the floor mats were always wet living in Portland, Oregon, we get up in the morning, our car would be completely dry on the inside. Just because of the desiccation that occurred there. So, there are a couple of cases where I wouldn't recommend it if it's a small studio apartment and there's no place for that to blow.

Yes, I'd think about venting in and out of the envelope. So Thurston, I'm gonna ask you, how are the tenants liking the heat pumps? Have you received any feedback yet? The tenants have shown they are pretty happy with the new adjustments in terms of distributing the heat to the units. They had some trouble with the controls, but once they were given information on how to actually operate the units, it ended up working out well. But they've been happy so far, you know. Being able to control your own comfort is a plus, and it was major for them being on central systems. So they appreciate that and it's been a good experience. Totally understand that. I visited my parents over Thanksgiving and for some reason it was 80 in our house, but I think that's just something as you get older. Younger kids were sweating it out in the kitchen. So I think that there was actually a question.

Geoff, you might be able to answer this one. So somebody asked if condensate was actually safe to water the plants or use on the lawn. Is that something that's possible or? Very much, I mean, it is actually drinkable. If you wanted to, I wouldn't recommend it because it's got all the particulates and possibly some machine oil that's coming off the fins and that sort of thing.

But yeah, it's non-toxic. Yeah, totally potable, and in fact, in places like Florida or even California, although there's not a lot of condensate being generated in parts of California, we actually encourage it to be dumped into the garden to take care of watering plants and that kind of thing. Okay. Very cool. Well, there you go. For those of you that are under water restrictions, some parts of the year. All right. So, let's see. So we have a follow-up on the previous question about switching from electric to heat. We now want to ask, what are important things to consider when you're switching from a gas water heater to a heat pump water heater? Any unique considerations? There are some considerations I think, you know, as Ben might point out.

You know, heck yeah, it's good for the planet, let's do that. But I would also say that you need to be considerate of where is that located? And oftentimes water heaters that are gas fired, whether it's a tankless or let's say a 40 gallon tall, there'll be smaller. And they may be in small outdoor closets adjacent to the building. California has about 93% of all the water heaters are gas, and it's an amazing array of where they're located. Sometimes they're in garages, sometimes they're inside the envelope, which is a little concerning, I don't know, concerning to me when you've got, Nox and Sox and formaldehyde coming off the burnt product. If you don't have proper ventilation, it can enter into the space or backdraft into there. But generally, as long as you have a place to put it, and you have sufficient power, and there are new products coming on the market, there's one being specially designed for the conversion from gas to electric, for the California, Arizona, Texas market, and that's the 120 volt product, it will run on a shared circuit.

So, anytime there's a plug available, say in a garage or nearby, it can literally be plugged in. It is not hardwired by an electrician. It is a plugged in unit. So, it is perfectly possible and products are becoming available. Those are standard tank units, there will also be split units. So that you can have your tank inside the house or inside where it normally is, and then you might hang the other unit in a crawl space outside of the house, or even up in an attic. So there's lots of options. Great. So, you know, one of the things that I've been hearing is about forthcoming projects, you know, things coming down the pipeline. So I think on behalf of everyone, I'm just going to ask all of our panelists, are there any tips or tricks to sort of be aware of forthcoming things? I know that I buy something the day that it goes out of style.

So help us out here. Well, I can speak to that for water heating. And it also works probably for Ben with his qualified products list. I'd encourage you to look at qualified products list that does evaluate and test their products, and compares it on an even playing field and makes it scaled to the geographic area. So, for ours, we view that as, we use the normal DOE UEF, which is the Uniform Energy Factor. Which is a standard they have applied to water heating across the nation, 67 degree ambient, 67 degree inlet water. We calibrated ours to the Northern climate. So we show what happens with 50 degree air, 50 degree water, so it works in colder climates, and we give you that performance factor.

We also are now including 95 degree air with 70 degree water. So, you can see this broad range. And I know NEEP is doing the same thing with some of their cold climate heat pumps and other qualified products lists are available. So, use a reliable third-party qualified products list. I would say, get smart about it, and feel free to reach out to any one of us at any time and ask us questions. Yeah, I would completely echo what Geoff said, and just add, you know, please reach out to us if you have any product specific questions, other than that, you know, our list is available to show what is qualified so far. Alright, very cool. And always, one of the best things about attending engagements like this is, that here's networking. Here's people that you can email, or just reach out to, to follow up on conversations or potential projects that you're working on. So, I would encourage everybody that's attending today to kind of use all the resources that you've been privy to today, to your advantage in the future.

And, you know, strike a conversation up, or reach out to any one of our panelists with a follow-up question that perhaps you didn't want to ask here. So we've got a couple more from the audience. Let's see if we can get to them. It looks like we have about 10 minutes left. So this next one. Are there instances where the cool air coming off a heat pump water heater could be used to cool interior air instead of air conditioning? So, for water heating, that does work.

I wouldn't rely on that as the only source of air conditioning because it only runs when you need the water reheated. So, here in the Northwest, our heat pump water heaters will run two to four hours, which is great, but it may not be coincidence when you need the cooling in the space. What's interesting is, we're evaluating a product right now, it looks very promising for commercial kitchens. It's 120 gallon heat pump system, a huge machine, but in a commercial kitchen, water heating is typically located where the dishwasher is, and I think the dishwasher will find this product to be ideal for what they're doing in their daily lives. I would say that it would be a much more typical to go the other direction and actually recover heat. So heat recovery, and then use that heat elsewhere in the building. That is one advantage of heat recovery VRF systems, which do have that branch box, which allows you to share the heat between zones. And in a very large building what can happen is, you would need heat on exterior of the building by the windows, and you may actually need cooling in the core of the building.

So instead of, you know, generating that heat, you can simply share it between zones. So now I get to ask the question. You know, I have a couple of dollars in my pocket. I'm thinking about making a purchase or starting to do my research. A question to our panelists, are there any sort of incentives, or government incentives that encourage homeowners to make these changes, these energy efficient changes? Same question for multifamily building owners, you know. Any government incentives that we we're aware of, that we wanna share? So I'll take a whack at it. First off, there are generally a lot of utility incentives. If you're eligible and you can take advantage of them, and I would encourage you to always call your utility or look it up on their website to see if that's available. There are some state tax incentives that I would encourage you to look into. I'd talk to your financial advisor about that. And the Build Back Better program is gonna have significant amount of incentives for conversion and or upgrades for energy efficiency. So, for example, heat pump water heaters have enjoyed a $300 federal tax credit for the last, I don't know, eight years or so.

That's probably gonna go closer to $900 if things go the way they're supposed to. Which is substantial because with a heat pump water heater and a $900 incentive or utility incentive, they'll basically be no cost to the end user, and or building owner to run that. Now, as central systems, you're gonna have some interesting added benefits beside those incentives. There is gonna become more of a need for demand response, or load shifting capability. These central systems will be able to do that. A small residential tank can shift a modest amount, but in a central system, you can actually move a significant amount of KW, which is gonna be a big interest to the utility, and the management of the grid in the integration of more renewables. So, that will become a big element in future incentives and reasons for selecting a heat pump solution and not a gas boiler. I definitely agree with Geoff, I would say same answer for space heating and cooling.

Check with your utility, investigate what's available for rebates, typically administered by various program administrators in your area, and that can help you when your calculation of the cost. And I would say that in general, the efficiency and the reduction of operating expenses becomes a much larger piece of the pie than what you'll get from rebates. But definitely investigate as much money as you can get back. Mark, I might add something here, sorry. If there are any utility program managers onboard, we've done lots of studies here in the Northwest, and by far and away, we see the most successful programs that are being administered or what we refer to as, instant rebates. So when you go to a distribution house or you go to your retail outlet, the price of that water heater is already marked down and you're not having to fill out paperwork. Paperwork will be the death of anybody signing up or even moving the market. We've seen huge change when it's instant and it just dribbles in if it's a fill out this paperwork, you got a four page document, you've gotta give your pet's birth certificate and you know, where you got it and what pound and what it's pedigree.

It's just ridiculous. It needs to be instant. If we can go to that direction, you'll find a lot more uptick in it, and the plumbers, the installers, everybody will just embrace it so much more quickly. I think that that's probably just generally true. You know, it's just harder to get things done when you require that much paperwork. We've come up with neat phrases for red tape and such. But as a little birdie actually just told me, that there's also a cool website that people can go to. It is called dsireusa.org. That is D-S-I-R-E, and that stands for Database of State Incentives for Renewable and Efficiency. So this is something that you could go to and see what your local jurisdiction is doing. I actually previously lived in Seattle, came to D.C. from Seattle, and I will also echo that Seattle Public Utilities constantly running things, awareness campaigns about credits that you might be eligible for.

Because they're the first people to hear about any new funding available or anything that can be offered to the public. So that is a wonderful resource to consult, hopefully in other cities and jurisdictions to see what is available to you to make some of these decisions. And then of course as Ben points out, if you want to go the ethical route, it's a pretty easy cost benefit analysis right there.

You know, Geoff, one of the things that I was actually thinking about when you were making your presentation was the factory built units that come and are shipped straight to the straight to the, I guess, job site, if you will. And I know in some of the work that I do, we've seen that with modular housing and that's a lot of cost savings in the process, and of course, a lot of, like you said, four hours for an install time is, you know, that's great for everybody, for the traffic, for the residents coming in and out.

I'm wondering, do you see some of the, if there are any savings due to, you know, efficiency within manufacturing inside of a factory off site, are those savings going, you know, are they typically passed to the customer? Or is this just more of an efficient way of getting things done and getting them installed quickly? Oh, I think you will see some efficiencies with that. I mean, it's an excellent observation. Much like you could build your car in your garage if you wanted, if you ordered all those parts in one by one. But on the assembly line, they can do it right and fast, and it's done to quality standards. What we found in the water heating world is these systems have been installed and the plumber and the designer aren't necessarily on the same page or the same blueprint, and they end up, you know, putting the goes into in where the goes out to should go and that kind of thing. So, the factory installed will improve the efficiency of what's going on.

You don't have to train a new plumber every time, it comes as a module, they can actually build fixtures so that they can do this correctly, repeatably, and then they have test procedures to verify and validate operation. And then, because it's coming in basically with one inlet a pipe going from the city water, and then another one going out to the building or multiples, depending upon how it's designed, you create some efficiencies that you can not do when you do a site-built. Plus the manufacturing is often done in the areas where the cost of labor maybe cheaper and jobs are more available.

So all our water heating right now for unitary is all done either in the Southeast, a little bit in Texas and that location. But what we're finding is, industries that have converted from an old technology that's no longer viable to say water heating, they'd have a surplus of very talented workforce. So it is a viable option. Some of those savings are passed along because they don't understand that the labor rates in Seattle are super high, and consequently, they just say, well, here in North Dakota, for example, it's working just fine paying a journeyman welder $25 an hour. Whereas a plumber in Seattle is starting, they roll the truck at $150 an hour.

So career options, if anybody's looking for a good thing. My mom always said the same thing about electricians. So we're at time right now, 1:30. Two things I wanna do very quickly though is, the first is just thank all of our panelists. I thought excellent presentations, very informative, great question and answer. So I just wanna thank all of our panelists for your time today, and the knowledge that you shared with us. And then secondly, lastly. I'd like to invite you to our next webinar that starts in 30 minutes. It will be Shoo Fly, Don't Bother Me: Minimally Invasive Exterior Retrofits. So I really hope to see all of you at two o'clock. And I will wrap it up here. Thank you everybody for attending.