Hey there, guys. Paul here from TheEngineeringMindset.com. In this video, we're going to

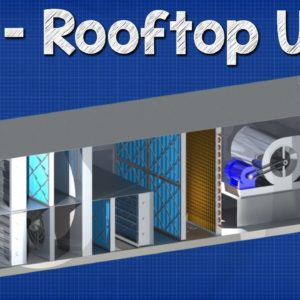

be discussing rooftop units. Coming up, what is an

RTU, where are they used, how do they work, the different types, as well as the components

inside, such as heat exchangers, filters, fans, ductwork,

grilles, air hoods, et cetera. If you like the information

you see on this channel, and I really hope you do,

then it's easy to keep your education going by

heading up to Danfoss Learning who have kindly sponsored this video. Danfoss want to encourage

people all around the world to learn as much as

possible about engineering. So they built a free

online learning platform packed full of courses on

pretty much every conceivable engineering topic,

including additional lessons about rooftop units. All you have to do to get

started is click the link in the video description

below, create your free Danfoss Learning profile, and

then pick your first class. Pop engineers quiz, what does a package air

conditioning unit mean? Tell me your answers in

the comments section below, and I will reveal the answer

at the very end of the video.

Okay, rooftop units, as the

name suggests, rooftop units, or RTU for short, are

located on the roof of shops and small commercial buildings

to provide air conditioning to defined areas. These are packaged air conditioning units, and they are so popular because

they are simple, compact, self-contained, all-in-one HVAC units. Their purpose is to

distribute conditioned air within defined areas of a building. Rooftop units are connected to ductwork which provides a defined

route for the conditioned air to travel along.

Now in our last video, we looked at air handling units, or AHUs. I would encourage you to watch

that if you haven't already. Links are in the video description below. If you have watched that,

you'll probably notice that these units are very similar. Rooftop units are a type of air handler. The main difference is that

they are usually more compact, and they're always installed on the roof. So they need to be more

robust and weatherproof to deal with things like sun,

rain, snow, wind, et cetera. Additionally, AHUs will often

be connected to central plants such as chillers and boilers

to provide the heating and cooling, but RTUs are self-contained and have everything they

need all in one unit.

That's why they're called

package air conditioners, and we'll look inside

some models just shortly to understand why. There are many types of rooftop units, and we'll look at four

different typical versions starting with the most basic. This first unit is fresh

air only so that means that there's no recirculation

of air occurring. It takes 100% fresh air and conditions it. The return air is usually removed

by an external exhaust fan to balance the air pressure

within the building, but we won't cover that

part in this video. First, we have the housing. This needs to protect all the

mechanical and the electrical equipment inside the unit

from the sun, wind, rain, snow, frost, et cetera. There will be some access

panels built into this to allow engineers to

access the components inside and perform maintenance. At one end, there would

typically be an air hood. This is where the outside ambient air will be drawn into the machine. The hood is shaped this way to

stop water, snow, and debris from entering into the unit. There will usually be

a mesh across the inlet of the air hood which will

prevent wildlife and objects from entering, as this

will cause blockages and damage the fan.

The next thing we might

find are some dampers. Not every unit has these, but

newer models typically do. These are basically sheets of

metal which rotate together. They open fully to allow

air to enter the unit or they close to seal

the unit and prevent air from entering or leaving. Some dampers can vary their open position to somewhere between fully

opened and fully closed, especially if recirculation is used, and we'll look at that later in this video after this basic model. After the dampers, we'll find the filters. These will usually just slide

out from the service door. Their purpose is to clean

the air by capturing the dirt and the dust which is

contained within the incoming fresh outside air.

If we don't have filters

installed, then the fan, heat exchangers, mechanical

components, and the ductwork are all going to slowly

be covered by the dust, and it's going to reduce the effectiveness and the efficiency of the machine. If too much dust builds

up on these components, then it's eventually going to lead to the failure of the machine.

After the filters, we'll have some coils. These coils will be used

to cool or heat the air by adding or removing thermal energy. Depending on where in the

world the RTU is located and the ambient conditions it faces, some units will be cooling only, though occasionally they

will be heating only, and some will be heating and cooling. If the unit is cooling only,

then it would typically have a single coil which is connected

to a refrigeration unit. If the unit is heating

only, then it will either be connected to a heat pump, a gas burner, or an electrical heating element.

If unit is heating and

cooling, then it'll either have two heat exchangers, where

one will be a cooling coil which is connected to

a refrigeration unit, and that will provide the cooling, and the other will likely

be a true heat exchanger which is connected to a gas burner, or it might be an electrical

heater to provide the heating. Alternatively, a unit might

provide both heating and cooling using a single coil which

is connected to a heat pump. We've covered heat pumps

in a previous video. Links for that are in the

video description below. Most units will use a refrigeration system to provide the cooling. The compressor, condenser,

fan, and controls are usually located at the rear

of the unit or at the side, and these will be used to

reject the heat and keep it away from the intake and the conditioned air which is inside of the unit.

After the coils, we'll find the fan. This is usually a belt-driven

centrifugal type fan, but it can also be an EC type fan which are more energy efficient. The fan pulls the air in from outside then through the dampers, filters, coils, and they will push this

through the ductwork to be distributed around the building. That's our most basic

type of rooftop unit. So what else might we find? Some units might

recirculate the internal air for a return ductwork system. This is used to save

energy, especially in winter when the outside air is very cold and a return air is very warm. We can use this to reduce

the heating load by mixing some of the warm return air in with the cold fresh air intake.

In this design, we find a

return air damper in the unit. This will work in sync

with the intake air damper and the two will vary their

position to change the mixture of how much fresh air

and how much return air is passing through the unit. There will always be a

certain amount of fresh air entering into this type

because otherwise the building would simply fill up with CO2 and create a very unhealthy atmosphere. As the damper opens, the

suction of the fan will pull air in through the ductwork. When the damper closes,

no air will be drawn in.

Another version we'll come across, and this type is very common,

in this design, we again have the return air damper, but this time some of the air or all of the air can be rejected to atmosphere. The temperature of the

outside air and the return air and sometimes the CO2

levels of the return air will dictate how much air will be rejected and how much will be

mixed and recirculated. In this type of unit, when

the outside air temperature is below or close to the

desired indoor air temperature, 100% fresh air can be

blown into the building, and none of it will be recirculated. All of it will be rejected

as the cooling demand is met. This is referred to as free cooling cycle or an air side economizer cycle. The final version we'll

look at has a heat wheel built into the unit. This is growing in popularity

with the increasing need for energy efficiency in

buildings to reduce CO2 emissions but also energy and utility costs.

This unit first pulls

air in through the hood. The amount of air entering

is controlled by the damper. The air then passes through

a filter to catch the dirt and the dust and protect the

surface of the heat wheel. It will then pass through the heat wheel. The heat wheel is a rotating

heat exchanger which picks up the waste heat or CoHP from

the return discharge air, and then transfer this over

to the incoming fresh air without the two air streams mixing. These heat wheels are

not completely airtight. So a little bit of air mixing will occur. The heat wheel is used

to offset the heating and sometimes cooling demand

when conditions are right. This will save energy,

as well as utility costs. After the heat wheel, the air flows through to another filter. Just before the filter, we have a damper on the return air stream. This allows us to recirculate

some of the return air into the fresh air,

and the quantities vary by using the dampers.

Not all heat wheel RTUs

will have this feature. Some will use only 100%

fresh air intake and extract. If the unit doesn't have

the option to recirculate, the unit probably will not

have a second filter back here. After this, the air will flow

through the heat exchangers which will heat or cool the

air to the desired temperature. The fan will then distribute

the air through the building via the ductwork to the

designated locations. The return air is then

pulled back into the RTU for the return ductwork. Once it re-enters the

RTU, it has the option to either recirculate some of the air back into the fresh air

intake, otherwise it will all pass through a filter and

then through the heat wheel to recapture the waste heat.

After the heat wheel, we

might find an extract fan. Otherwise, the pressure

caused by the main supply fan will force the air out in some designs. The air then passes

through the extract damper which is used to vary the

volume of return air mixing as well as the pressure

inside the building. After that, it passes through

a grille which just stops objects and wildlife from

entering into the unit. It will then be ejected from

the system into the atmosphere. Alright, before we wrap things

up, I just want to remind you to sign up for your free

Danfoss Learning profile. Doing so, gets you access

to over 1,500 e-lessons including several about rooftop units. Go give it a try now. Links are in the video description below. Engineers quiz answers. At the beginning of the video, I asked you what does the term package

air conditioning unit mean. The answer is that package

air conditioners contain all the main components within one casing.

So that's the fans, the

filters, the cooling and heating coils, the compressors,

the controls, et cetera. The entire system is

prefabricated into one package. It comes from the manufacturer, and can be quickly installed as one unit. Okay, guys, that's it for this video. Thank you very much for watching. I hope you enjoyed this

and it has helped you. If so, then please don't forget to like, subscribe, and share, and leave your questions in

the comments section below. You can also follow us on

Facebook, Instagram, Twitter, and TheEngineeringMindset.com.

Once again, thanks for watching..