As a heating and cooling

professional, you work hard at what you do and take pride

in getting the job done right. That's why we're here to talk

today about measuring air flow for residential air

conditioners and heat pumps. We're not selling anything and we don't represent any

one's products or services. But as independent energy

efficiency researchers, we've had the opportunity to

make measurements on hundreds of residential systems. And we'd like to share

that experience with you. >> In this video, we'll talk about why proper air

flow is important, how it affects system efficiency

here, in the upper Midwest, and we'll go through

the pros and cons of different ways

to measure air flow. >> All right. Let's get started. >> Great. >> Okay. Here we are looking at a nice new high efficiency

gas furnace that also serves at the air handler for a two-and-a-half-ton

central air conditioner.

The question is, in the summer

is this furnace producing the right amount of air flow

for the cooling system? We'll find out in a minute,

when we actually test it. But first, let's talk about how

much air flow we're looking for and the consequences of not

having the right amount. So, you probably already know that manufacturers are

generally looking for somewhere in the range of 300 to 400

cubic feet per minute per ton of cooling capacity, in

terms of cooling air flow.

So, here, we'd be

looking for something in the 800 to 1,000 CFM range. And I'm sure you already

know the consequences of having air flow

that's too low. You're looking at very cold

evaporator coil temperatures, and potentially a frozen

coil and all the problems that go along with that. But when we test systems

here, in the upper Midwest, what we actually find is

that we're much more likely to find air flow

that's too high. And that's probably because

here, where it's cold, we tend to install big

furnaces with big blower motors. And we pair them up with

small air conditioners. And that's bad, too, because

high air flow creates its own set of problems. Number one, it hurts the

ability of the system to dehumidify the air. And it also means a lot more

blower electricity going through the system. And it just makes for a

noisier overall experience and less comfortable overall

experience for the homeowner. So, we typically find that about

half of systems that we test in our research in this part of the country have

air flow that's higher than 400 CFM per ton.

But only about one in ten have

air flow that's below 300 CFM per ton. When we correct those

air flow problems, we typically see an improvement

in efficiency performance of about five percent. But we've seen increases

as much as 30% when air flow was

really a long ways off. All right. So, we're going to take a look and see how well this system

is doing, in terms of air flow, by measuring it with a

number of different methods. There are lots of different ways

to go about measuring air flow. Here, we're going to

concentrate on just a few. We'll talk about using

a calibrated flow plate. We'll look at air flow by

measuring velocity in the ducts. We will look at static

pressure and how we can use that with manufacturer's

literature, to estimate air flow. We'll talk about adding up

air flow by measuring flow from individual registers. And finally, we'll look at

the temperature split method for measuring air flow.

Let's get started. >> Let's start with this device,

which is a calibrated flow plate that takes the place

of the filter. Basically, air flow is

very predictably correlated with the pressure drop

across this plate. So, just by measuring

the pressure drop, we can get a good measurement of the total air flow

going through the system. We really like this device. And we use it often

in our research. It's accurate and

relatively easy to use. In the kit, you get basically,

two flow plates, different sizes with a bunch of spacers

that allow you to adapt the particular plate

to any filter slot size. The main downside is

the up-front cost. Which is about $800, not including a good

digital manometer. Which would be a

digital, or another way to say it, is a pressure gauge. The one we have is made by the same manufacturer

as the flow plate.

It is right here,

that we'll be using. So, it can do the pressure to

air flow translation for us and give us a direct

reading of air flow. We combine the flow plate

with a pressure gauge. We can read CFM, cubic

feet per minute, directly. So, let's take a

look at it in action. Okay, I'm going to

drill the hole for the supply pressure

reference tap for the TrueFlow plate. This allows me to understand the

supply pressure at this point with the filter in place, and with the TrueFlow

plate in place. Which. [ Drilling Sound ] By measuring that pressure,

I can see the difference in resistance between the

filter and the pressure plate.

Helps me calibrate

the air flow and CFM. I'll stick the static

pressure probe in, point it towards the air stream. So, now that the

pressure tap is in place in my supply trunk line. I've turned the air handler on. We've turned it in the cooling

mode to get cooling speed. My digital manometer is

reading static pressure in the supply trunk with

the filter in place. I'm going to hit enter so that

my digital manometer records that pressure. Next, I'm going to

remove the filter and insert the TrueFlow

pressure plate. So, now that I have the

TrueFlow plate installed, then I've covered up the

filter slot opening just to eliminate any leakage

that might occur there. Now, I hook the TrueFlow plate

up to my digital manometer. My digital manometer is set to

read the particular flow plate.

It's been programmed with

the appropriate flow plate. We hook up the pressure

hoses on either side of the pressure plate to

the digital manometer. And the manometer is going to

read out cubic feet per minute, CFM, of air flow across

that pressure flow plate. Right now, we are reading

seven ninety, seven hundred and ninety-eight

hundred CFM, I have here. So, that's right on the low

end that we're asking for, for this two and a half ton

air conditioning system. That's it. It's very simple, easy to use. And as we stated

earlier, very accurate. >> Okay. So, our second way of measuring air flow

involves measuring the velocity of the air in the ductwork. If we know the velocity

of the air that's going through a section of duct,

in say, feet per minute. And we know its cross

sectional area in square feet, we can put those two pieces

of information together and calculate cubic

feet per minute. Now, there's a couple of

different ways that you can go about getting at this velocity.

One is to use a pitot

tube, like this one, where you have a short

tube with a hole in the end that you face into

the air stream. And the greater the velocity, the greater the pressure

on that hole. And by measuring that pressure, you can translate

pressure into velocity. But today, we're going to

use a different device. And that is this

hot wire anemometer. Now, this thing works by

having a very tiny little wire in its tip that's heated. And as the air goes across

that heated wire, it's cooled.

And by measuring

that cooling effect, we can translate

into air velocity. Now, it would be great

with either the pitot tube or this anemometer, if

we could just stick this into the ductwork

in any given spot, take one reading,

and be done with it. But the problem is that air

velocity varies on the inside of the duct from one side to the

other and from front to back. And sometimes, if varies a lot.

So, if we really care about

getting a good measurement of air flow, we're really

gonna need to make a number of measurements to get the

average velocity of the air through that section of duct. So, okay. So, here we are on

the backside of the furnace. And I've marked the location

of five holes that I'm going to drill in this nice long

straight section of return duct. And those holes are not

exactly in the same place. We won't go in today, why

they are where they are.

But you can look that up,

online for more detail. But we're just going to go

ahead and drill five holes. And we'll run our

hotwire anemometer through each one of them. [ Drilling Sound ] Okay. So, I've drilled

my five holes. And now, what I'm going to do is

take this probe, and I'm going to extend it all the way

into each one of the holes. And then, slowly withdraw

it while we're using our anemometer, here, to

average the velocity across each one of those holes. Alright, last hole. So, we've done our

five traverses through the five holes. And we've got our

overall average velocity of 540 feet per minute. And when you multiply that

by the sides of the ductwork, which is ten inches

by 23 inches, that works out to

just about 860 CFM.

But I can tell you

that we saw everything from 190 feet per minute,

with the velocity, there, to over 800 feet per minute. And one thing we can show you, is because this little

unit can data log and we recorded those traverses,

we'll show you a graph of what those five velocity

traverses look like. So, another way to

measure air flow is to take some static

pressure measurements at different places

in the system. And then, take that information

to the manufacturer literature where we can look up air flow as

a function of static pressure. And we've really got

two choice, here. One is this static pressure rise

across the air handler, itself. And the other one would be

the static pressure drop across the evaporator coil. In this case, we're

going to use the rise across this furnace unit, where we have the

literature available.

And you can see that we've put a

static pressure probe down here in the blower return cabinet. And then, we have

another one up here in between the furnace

outlet and the bottom of the evaporator coil. And we have the system running. And you can see that we're

measuring just a little under half an inch of water

column across this system. So, with the manufacturer

literature in hand, we can look up, based

on the speed tap, the model of the furnace, and the static pressure

rise that we're seeing. And we read off of the chart that we are seeing

about 975 CFM. Which is just a little bit

higher than we measured with the flow plate, but

in the same ballpark. Now, this method will work well if you have the manufacturer's

literature. It won't work at all, if you

don't have that available. And generally, it's probably

preferable if you have a choice, to make the measurement using

the total external static of the furnace, rather than the

pressure drop across the coil. Because with the coil,

you can have issues with, is the coil wet,

is the coil dry? And if that coil has been

in place for a while, it may have some

dirt buildup on it.

And that could affect the

readings that you get. >> Okay. Another way to

measure air flow is at each of the registers using

our hot wire anemometer. The hot wire anemometer

measures feet per minute, if we know the register size and its net free area

in square inches. So, it'll require going to the manufacturer's

specification sheet to make sure we know the open

area of the face of this grille. The hotwire anemometer

measures feet per minute. And we have to do a

traverse across that register to get an average

feet per minute. Then, we multiply that by

the square feet opening of the register. And we then are able to

calculate cubic feet per minute. So, I'll start our traverse

across this register. And we'll take several passes. Now, measuring air

flow like this is great for diagnosing comfort problems

and distribution issues. But we don't generally

recommend it for getting at system air flow back

at the air handler.

It just takes too long to

measure all of the registers in the home, and there's too

much uncertainty from adding up all those individual

register measurements. Maybe you're wondering how

accurate these methods are. And we were, too. So, we made one extra

measurement on this system, using a calibrated fan to

match the system pressure and give us a very accurate

measurement of system flow. Compared to that gold standard,

the other measurements are in reasonable agreement. The flow plate measurement

was a bit lower. And the measurement based on static pressure

was a bit higher. But they were all

within ten percent. We didn't try to measure system

flow from register measurements, because if would

have taken too long. And the temperature split method

is just an indicator of flow, not a direct measurement. Plus, we couldn't do that test because the indoor

conditions weren't right. Generally, we favor

the flow plate test. Because it takes a quick and

reasonable accurate value. The hotwire anemometer

approach can be accurate, but it takes more time. The static pressure

approach is the quickest. But we have found that the

readings can vary some, depending on where you

measure the static pressure.

And you have to have

an air flow chart for that equipment

you're measuring. But our tests on this

particular system show that if you take your

time to do it right, you can get good air flow

measurements using a number of different techniques. One other note; if you're way

above sea level, you might need to make adjustments for

air density at altitude. >> One final method for assessing cooling air flow

is a really easy one to do, but you can only do it

under certain conditions.

And it's called the

temperature split method. And it's a lot like

measuring temperature rise when you're assessing

air flow for heating. In that we're looking

at the difference between the warm return

air that's coming back to the system, and the cool

supply air that's coming out the backside of

the evaporator coil. That temperature

difference it called the ''temperature split''.

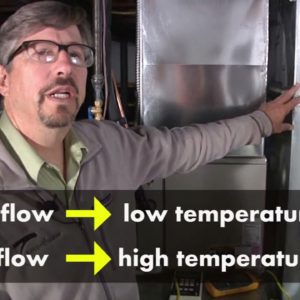

So, if we have a system that's

running really high air flow, that air is going over that

evaporator coil very quickly and it's not getting

cooled down very much. So, this temperature difference,

or this temperature split, will be on the low side. On the other hand, if we have a

system with very low air flow, that air is dwelling on that

evaporator coil for a long time, it's getting cooled down a lot. So, we will see a

large difference between the return air and the

supply air that's coming out.

And by gauging the magnitude

of that temperature split, we can get a sense of

whether our air flow is in the right ball park. But there is a rub. Only part of the

energy that's going into this cooling coil is going to actually cool the

temperature of the air. The rest of it is going to

removing humidity from the air and it doesn't reduce

the temperature. So, depending on how humid

the air is, that's coming into the system, it will affect

the target temperature split that we're looking for. If we have very dry air that's

coming in, we'll be looking for a very high temperature

split for our target. On the other hand, if we have

really humid air that's coming back on the return

side, we'll be looking for a relatively low

temperature split.

So, to make this

measurement, all we really need to do is measure the

temperature on the supply side. Remember, measure

the temperature, the dry bulb temperature, and the wet bulb temperature

on the return side. And then, use our target

temperature split table to look up, based on

return dry bulb temperature and return wet bulb temperature,

what our target number is. And then, compare that to

what we actually measure. But there's one other thing

that we have to worry about. If we see a low temperature

split, it could be that

air flow is high, but it could also be

something else that's wrong with the system. For example, if refrigerant

charge is low, our system will not be putting

out its full amount of cooling, that in and of itself will lead

to a low temperature split. And if we're not careful,

we could misdiagnose that as an air flow problem, instead of what is really

a refrigerant problem. On the other hand, if we see

a high temperature split, then that's a pretty

good indication that we have low air

flow on our system.

Now, the final consideration is that our temperature split

target table only works for a certain range of dry bulb and wet bulb return

temperatures. And if we're outside of

that range, we're not going to be able to make

that measurement. And that's the cases,

here today. We're off the charts

as far as being able to get a target temperature

split. So, we won't be able

to measure it, today. Well, there you have it. Some of the ins and outs of various ways to

measure air flow. I hope this inspires you

to start measuring air flow on the systems that

you install or service. >> If you found this

video useful, please watch our other

videos related to details of our research findings

and tips for homeowners. Thanks, for watching..