Introduction: Navigating the Challenges of HVAC Work

In the ever-evolving world of HVAC, there’s never a dull moment, especially when you’re faced with unexpected twists and turns on the job. In the YouTube video titled “Installer Failed To Return On Several Projects Where I’ve Started to Pick up Work! #hvacguy,” we dive deep into the trials and tribulations of a meticulous HVAC technician navigating a mobile home park project where newly installed systems are failing to launch. Our host shares firsthand experiences that range from troubleshooting unresponsive thermostats to dealing with the unforeseen chaos caused by a fire suppression sprinkler system. From failed installations to urgent repairs, this video sheds light on the complexities and unpredictability inherent in the HVAC industry. Join us as we unpack the lessons learned from these real-world encounters and explore what it truly takes to keep the air flowing and homes comfortable. Whether you’re a seasoned pro or just starting in the field, there’s plenty to glean from these behind-the-scenes revelations.

Understanding the Impact of Poor Installation Practices on HVAC Systems

“`html

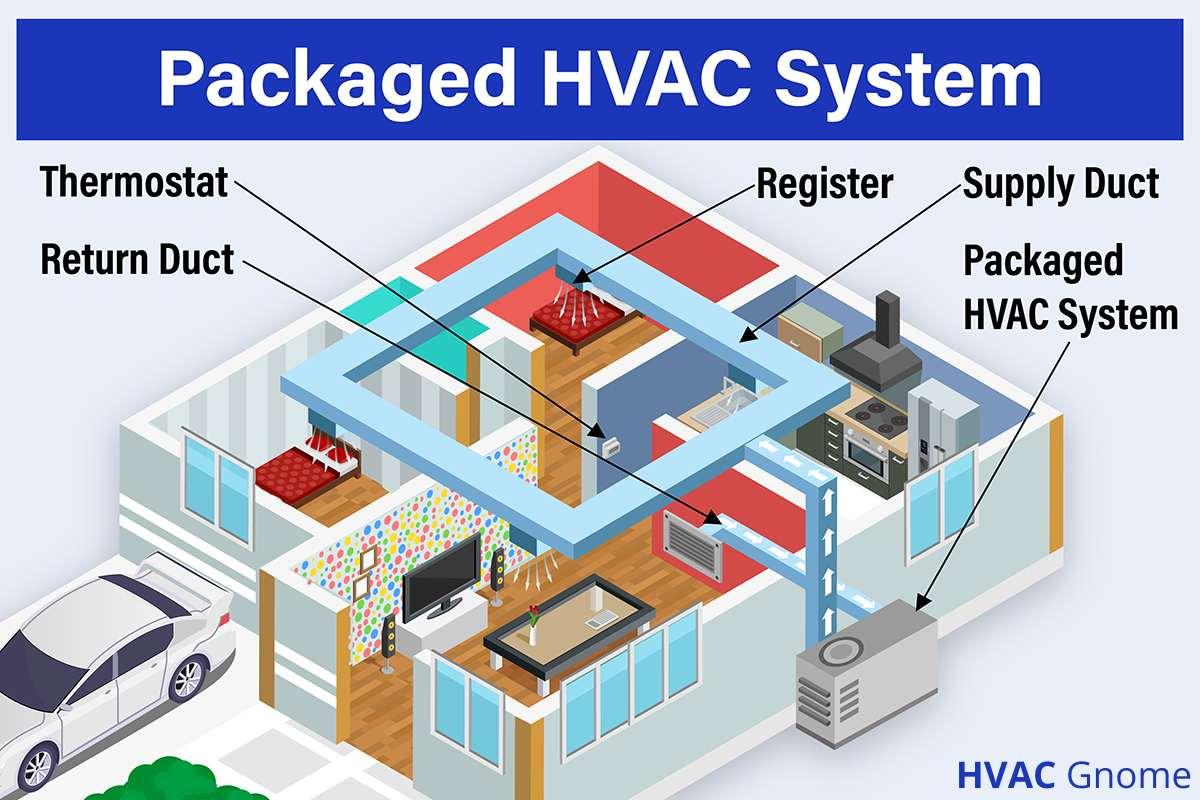

One of the most significant consequences of poor installation practices is the immediate impact they have on system functionality. For instance, in a recent project, an Ecobee thermostat was found to be non-functional due to improper wiring, leaving residents without cooling in sweltering temperatures. This situation illustrates the importance of meticulous installation protocols. When technicians neglect crucial steps such as ensuring that all components are properly connected, they not only jeopardize the efficiency of the HVAC system but also put the comfort and safety of homeowners at risk. Basic issues like these can lead to major discomfort, especially during peak heat or cold seasons.

Moreover, operational failures often result in extensive and costly damage that could have been avoided with diligent practices. One project turned catastrophic when a sprinkler above an air handler burst due to excessive heat during installation. Not only did this lead to water damage and the need for floor replacement, but it also delayed service for other clients relying on timely HVAC repairs. The ripple effects of such mistakes are profound; they create a chain reaction that can drain resources, increase labor cost, and tarnish reputations. As HVAC professionals, it is crucial to uphold high standards of excellence during installation to safeguard client satisfaction and preserve the integrity of our work.

“`

Navigating Troubleshooting Challenges in Compromised Installations

html

Troubleshooting compromised installations can feel like navigating a maze, especially when the systems in question have never been started up correctly. Presenting a multitude of potential issues, such as a blank thermostat or an improperly connected electrical system, brings challenges that require methodical investigation. Start by confirming that all necessary components are powered— check the surge protector, verify the connections, and ensure there are no blown fuses. A cursory glance won't suffice; delve deeper into the setup, as my recent experience highlighted the importance of a thorough inspection. Missing fuses or disconnected thermostats can lead to unnecessary downtime and frustration, not only for the technician but also for the end users left without a functioning HVAC system.

Additionally, when faced with unexpected situations, like water damage from an improperly monitored sprinkler system, it's crucial to have a well-prepared approach. This incident reminded me that the physical environment can profoundly influence our work. Documenting each discovery is essential—not just for current projects, but also as guidance for future installations. A quick consult with resources that can assist with repairs, such as estimates for replacement or repair, can be invaluable. Utilize checklists and tables to ensure nothing slips through the cracks, as these tools can help clarify the steps needed to get compromised installations back on track effectively.

Action Item

Purpose

Power Check

Confirm all components are energized

Fuses Inspection

Identify and replace blown fuses

Thermostat Wiring

Ensure proper connection and functionality

Preventive Measures to Avoid Costly Repairs and Service Callbacks

html

To prevent costly mishaps during HVAC installations, it’s crucial to implement proactive strategies. First and foremost, thorough training of all personnel can drastically reduce installation errors. This includes clear guidelines for handling common issues like wiring or equipment setup to ensure that every technician is equipped with the necessary skills. Additionally, regular on-site inspections before, during, and after the installation process can help catch potential problems early. These inspections should focus on ensuring all components are properly functional and compliant with safety codes, reducing the likelihood of callbacks or damages occurring after the job is finished.

Another critical strategy involves maintaining an organized project site and ensuring the proper tools are on hand. Investing in quality surge protectors and having backup equipment ready can save significant headaches. Implementing a communication protocol among team members can also facilitate quicker resolutions in the event of unexpected complications, such as dealing with equipment failures or faulty installations. Creating a clear checklist of all necessary steps and components required for each job can enhance efficiency and promote accountability, significantly lowering the risk of repeat service calls. Below is a simple checklist you can follow:

Task

Status

Inspect electrical connections

Test thermostat functionality

Verify equipment setup

Conduct final safety check

Enhancing Communication and Accountability within the HVAC Industry

In the fast-paced HVAC industry, miscommunication can lead to disastrous outcomes and significant project delays. The scenario shared reveals the importance of reliable follow-up after installations. When a technician fails to return for routine checks and troubleshooting, it not only jeopardizes the system’s performance but also erodes trust among clients. Clarifying roles, responsibilities, and timelines is crucial for maintaining high standards of service. Ensuring that each technician understands their obligation to revisit projects can significantly enhance the operation’s overall efficiency and client satisfaction.

Moreover, documenting every step of the installation process can provide a clear record for future reference. This can shield technicians from blame in the event of unforeseen issues arising after their departure. Adopting a systematic approach to communication can therefore pave the way for greater accountability within the HVAC sector. Here are a few strategies to consider:

- Establish regular check-ins with installers.

- Create a shared digital platform for tracking project updates.

- Implement protocols for documenting issues and resolutions.

The Conclusion

As we wrap up this discussion surrounding the insights shared in the video ”Installer Failed To Return On Several Projects Where I’ve Started to Pick up Work! #hvacguy,” it’s clear that the unexpected trials faced in the field can often lead to valuable lessons. From troubleshooting blank thermostats in mobile homes to navigating the complexities of air handler installs and the domino effect of minor setbacks like a sprinkler mishap, there’s always a story to tell in the HVAC world.

Our HVAC guy’s experiences remind us of the importance of thorough planning and vigilance during installations, as well as the necessity for good communication among team members and clients. Problems can arise unexpectedly, but they also pave the way for growth, ingenuity, and ultimately better service.

For anyone working in this field, or even those just curious about the behind-the-scenes realities of HVAC work, this video served as an authentic glimpse into both the challenges and rewards of the profession. So the next time you’re faced with a stubborn issue on the job or an installer who goes missing, remember: every challenge is an opportunity in disguise.

Thank you for tuning in! Don’t forget to comment with your own HVAC stories and experiences below. Share the lessons you’ve learned, and let’s continue to inspire and support one another in this journey. Until next time, stay cool and keep troubleshooting!