Hey there, guys, Paul here

from TheEngineeringMindset.com. In this video, we are gonna be looking at how a thermostatic expansion valve works. We'll be covering which refrigerator

systems use these valves, where to locate them in the system, what the valves look like, what's inside them, how they work, and what happens if they fail. Now, I just want to say

a very special thanks to Danfoss for sponsoring this video.

Danfoss have so many

solutions for those of us that work in the air conditioning

and refrigeration space. If you're watching this

video, chances are very good that you need high-quality

thermostatic expansion valves on a regular basis. And you should definitely look

at what Danfoss has to offer. Their line of products are

universal and adaptable delivering exceptional

quality and reliability, as well as a wide capacity

in refrigerant range. You can find out more about the Danfoss

thermostatic expansion valves in the video description below, or by visiting TXV or Danfoss.com.

The thermostatic expansion

valve is often shortened and called just thermal expansion valve, but both of these names are a bit long, and engineers like to find shortcuts, so they'll often just

use the acronym of TXV or even sometimes, just TEV, depending on where in the world you are. I've always known it as the TXV, so I'm going to refer to

it as this in this video. So, where do we find the TXV? Well, the thermostatic expansion valves are used in many refrigeration systems, everything from simple split units all the way up to big chillers.

Small refrigeration units, such

as household refrigerators, typically wouldn't use a valve, instead, they would use a

fixed orifice capillary, but we'll look at that in another video. Now, it doesn't matter which type of expansion device is used, it can all be found in the same location, which is just before the evaporator. Now, there are a lot of different designs for this valve out there, I've just got some

examples on the screen now. In fact, let's show you

a real-word example. So, this is the setup for an

air handling unit, or AHU, and it has two expansion valves because it has a large cooling coil.

The valve sits on the outside of the AHU at the evaporator entrance, and it meters the

refrigerant flowing into it. We'll have a look at exactly

how this works shortly. But you can see here the capillary tube runs from the powerhead

on the top of the valve all the way down to the sensing bulb, which is located at the evaporator exit, and that is measuring the

temperature of the superheat. So, let's just look at the main components inside the thermostatic expansion valve, and then we'll have a look at how the expansion valve works and why. If we pull apart the

thermostatic expansion valve, then we're going to see the

following main components: the valve body, which holds the components and has an orifice inside to control the flow of refrigerant, then we have the diaphragm, which is a strong, thin, flexible

material, typically metal, which flexes to apply pressure, then we have the needle or pin and seat, this moves up and down to restrict the refrigerant's flow path, the spring which counteracts

the force of the needle, and we've also got the sensing

bulb and the capillary line, which causes the valve to open or close.

As you can imagine, there are a lot of

different designs out there, for how these valves work. I'm just going to stick with

this simple version here to help you understand the

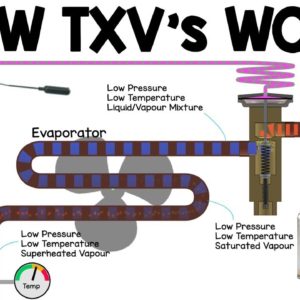

basic working principles. So, how does it work? Well, as we saw in the real-world example, the valve sits just before the evaporator and holds back the high

pressure liquid refrigerant from the condenser and

controls how much refrigerant can pass into the evaporator. The valve decreases the pressure to allow the refrigerant to

boil at lower temperatures.

For example, we're used to water boiling at around 100 degrees Celsius,

212 degrees Fahrenheit. That's because most of

us live near sea level, so the air around us is compressed by all the weight of

the atmosphere above us. However, if we went higher

into the atmosphere, say to the top of Mount Everest, then we would find that the water boils at only 70 degrees Celsius,

158 degrees Fahrenheit. And that's because we're higher up, so there's less atmosphere above us to push down on the water,

which makes it easier to boil. The boiling is essential for

the refrigeration system, as it will reabsorb the

heat from the air or water and carry this away to the compressor.

Also, just remember that the refrigerant has a much lower boiling point than water. The high-pressure liquid is

forced through a small orifice, which causes a pressure reduction, and as it passes through here,

some of it will vaporize, and the rest will remain as liquid. It's similar to water bottle spray nozzle. As you pull the trigger,

the high-pressure water is forced through the small orifice into a much lower pressurized atmosphere.

This causes the water to become

part liquid and part vapor. This mixture of liquid-vapor refrigerant is sprayed into the evaporator, where it will absorb heat

from the air or water which surrounds the pipe. In this example, the fan is blowing air

across the evaporator. As the refrigerant passes

through the evaporator and is exposed to more thermal energy, it will cause it to undergo

a complete phase change, and will then become a saturated vapor towards the end of the evaporator coil. During this change, there will be little to

no temperature change because of the latent heat, and instead, it will increase

in entropy and enthalpy. The refrigerant will continue

to pick up thermal energy, and when it does this after

the phase change has occurred, it will then start to

increase in temperature.

This superheats the refrigerant vapor, and the sensing bulb

of the expansion valve is monitoring this temperature

to control the refrigerant. So, let's have a look at an example. Let's say the cooling load increases, this will cause more

refrigerant to evaporate, and the superheat will increase, causing the refrigerant temperature to increase at the evaporator exit. We need to decrease the superheat, and we can do that by

allowing more refrigerant to flow into the evaporator. So, the pin will need to open more to let the refrigerant pass through. Inside the sensing bulb is a

small amount of refrigerant which is separated from

the rest of the system and constrained in a closed system to the area of just the bulb, the capillary tube, and the powerhead.

The sensing bulb detects

the temperature increase, which causes a small internal

reservoir of refrigerant to also boil and evaporate. Because the refrigerant is

constrained to a small area, it will cause the pressure to increase, and this pushes along the capillary tube up to the top of the expansion valve. This pushes down on the diaphragm, and that pushes down on the

pin, which compresses the spring and allows more refrigerant

to pass through the orifice. The valve will adjust to

find the correct position so that the force on the diaphragm is greater than or equal

to the force of the spring pushing in the opposite direction. This allows the correct

amount of refrigerant to flow, which decreases the superheat

refrigerant temperature at the outlet, and the

sensing bulb detects this and equalizes it. If the cooling load then

decreases back to normal, the superheat temperature will reduce. The sensing bulb will

detect this and will begin to reduce the refrigerant

evaporation in its chamber.

The refrigerant in the capillary then flows back towards the bulb and the main valve begins to close. The superheat temperature will also start to rise as this happens. Eventually, the valve equalizes out, and the correct amount of refrigerant will flow through to match

the superheat settings. Now, all of this happens automatically using this type of valve,

which is why it's so popular. There are other electronic

versions of this valve which can provide even

more precise control, but we will look at that in a later video. So, what happens if the valve fails or the wrong superheat settings are used? Well, if the valve didn't

react to the superheat, it could let liquid refrigerant

pass straight through and into the compressor. Compressors hate this because liquids can't

easily be compressed, and so the compressor will (explosion). Well, maybe not to that extreme, but the liquid will damage it, so make sure the superheat

setting is correct. Okay, that's it for this video. Thank you very much for watching. I also just want to say

another big thank-you to our friends at Danfoss

for sponsoring this video, I'll just remind you to

check out their high-quality thermostatic expansion valves

at cooling.danfoss.com.

You can also find more information in the video description below. If you like this video

and it's helped you, then please don't forget to

like, subscribe, and share. And if you have any questions, leave them in the comments section below. Also, don't forget to

check us out on Facebook, Instagram, and Twitter,

and also our website: TheEngineeringMindset.com..