When the sweltering heat of summer or the biting chill of winter rolls in, we often take for granted the silent workhorse of our comfort: the HVAC system. At the heart of this complex mechanism lies the compressor, a vital component responsible for circulating refrigerant and maintaining the ideal indoor climate. However, like any machine, it’s not immune to issues that can disrupt its performance. Understanding how to inspect the HVAC compressor for power is an essential skill for homeowners and DIY enthusiasts alike. Whether you’re preparing for seasonal changes or simply want to ensure your system is operating efficiently, knowing how to assess your compressor’s electrical integrity can save you time, money, and frustration. In this article, we’ll guide you through the process of inspecting your HVAC compressor, empowering you with the knowledge to keep your home comfortable year-round.

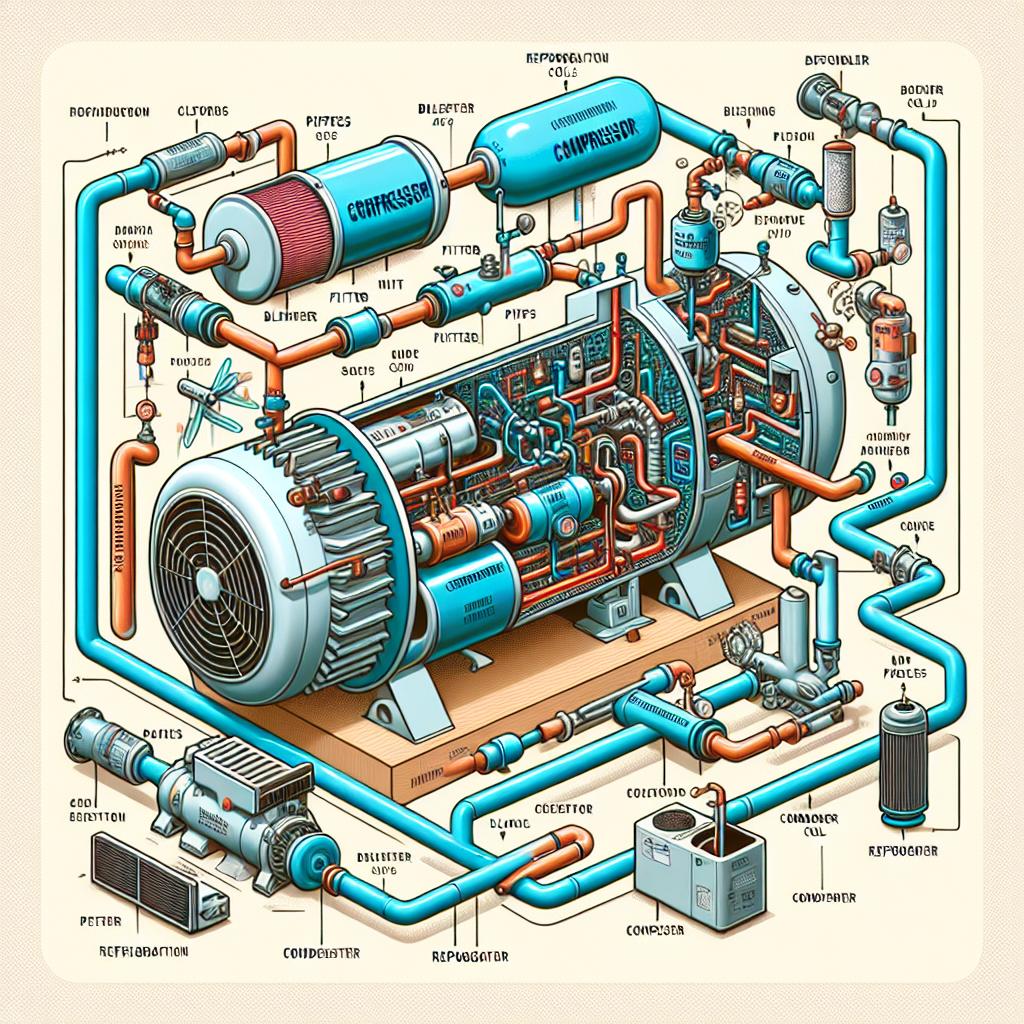

Understanding the Role of the HVAC Compressor

The HVAC compressor serves as the heart of the heating, ventilation, and air conditioning system, playing a pivotal role in maintaining optimal temperatures within a space. Its primary function is to circulate refrigerant throughout the system, compressing it and ensuring that heat exchange processes occur effectively. A malfunctioning compressor can lead to issues such as insufficient cooling, unusual noises, or increased energy consumption. Therefore, recognizing the symptoms of a failing compressor is essential for both comfort and energy efficiency.

When inspecting a compressor for power, there are several key areas to focus on:

- Power Supply: Ensure the unit is connected to an adequate power source, and check for blown fuses or tripped circuit breakers.

- Electrical Connections: Inspect all wiring for signs of wear, corrosion, or loose connections that could hinder performance.

- Capacitor Function: Test the start and run capacitors, as these components are vital for the compressor’s operation.

Utilizing a multimeter can provide valuable insights during your inspection. Below is a simple table illustrating the typical voltage readings you should expect based on different compressor models:

| Compressor Model | Voltage Reading (V) | Status |

|---|---|---|

| Model A | 230 | Normal |

| Model B | 208 | Normal |

| Model C | 120 | Potential Issue |

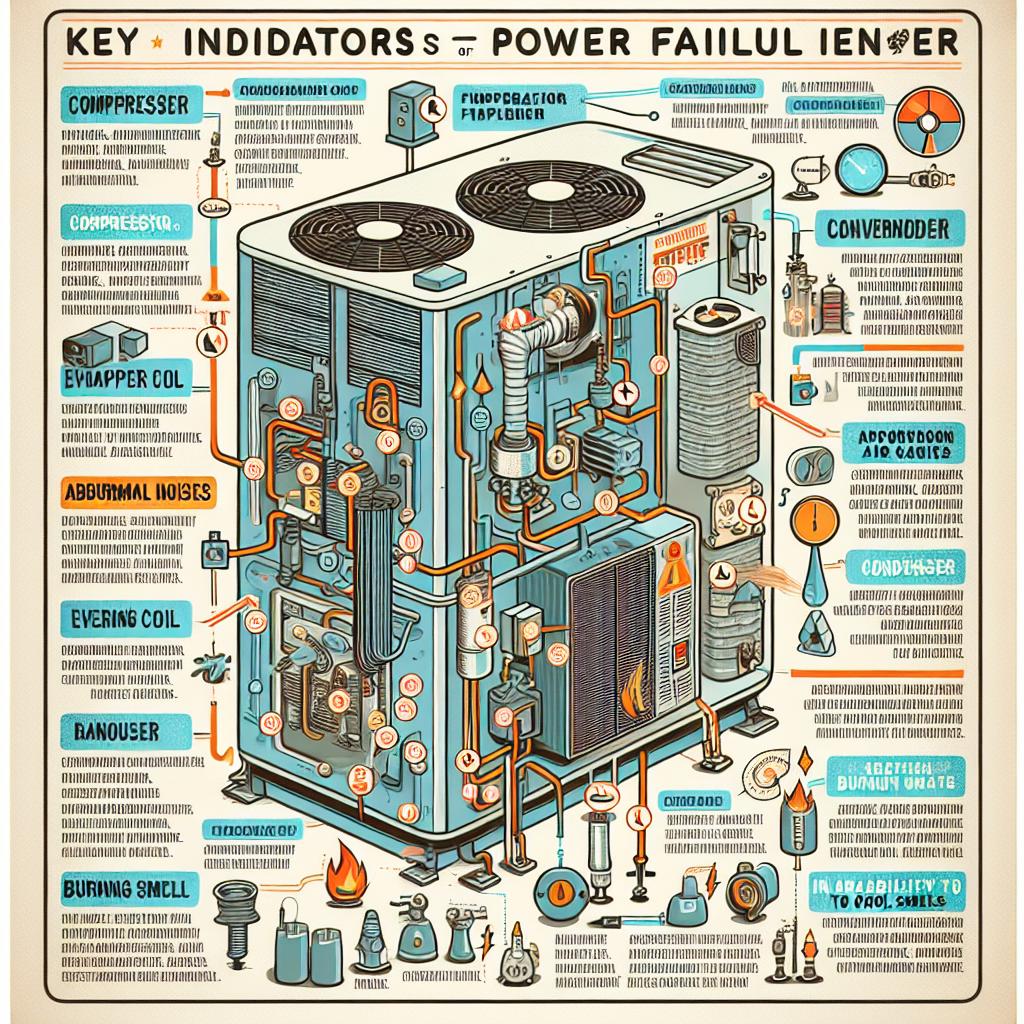

Key Indicators of Power Failure in HVAC Systems

When inspecting an HVAC compressor for power issues, it is essential to look for specific indicators that may signal potential failure. One of the primary signs to watch for is irregular sounds emanating from the compressor, such as grinding or clicking noises, which often indicate mechanical failure. Additionally, consider the following signs:

- Constant tripping of circuit breakers: This can point to electrical issues within the system.

- Unusual vibrations: Excessive vibrations can signify wear and tear.

- Signs of overheating: A hot compressor housing may suggest improper functioning.

- Inconsistent cooling: Insufficient cooling performance can be a red flag that the compressor is underperforming.

To facilitate a clearer assessment, you can refer to a visual representation of the power supply components associated with the HVAC system:

| Component | Description |

|---|---|

| Power Source | Electrical input to the compressor, critical for its operation. |

| Contactors | Devices that control the power flow to the compressor. |

| Capacitors | Provide necessary starting torque and power stabilization. |

| Relays | Switch signals to ensure the compressor operates only when needed. |

Step-by-Step Guide to Safely Inspecting Your Compressor

To begin your inspection, ensure you prioritize safety by disconnecting the power supply. Always turn off the breaker associated with the compressor and use a multimeter to double-check that there’s no voltage present at the terminals. Once you confirm that it’s safe to proceed, you can begin your visual inspection. Look for signs of wear or damage, such as frayed wires, extensive rust, or even physical deformation of the unit. Pay particular attention to gasket seals and connectors, which can indicate potential leaks if not in good condition.

Next, assess the operational components of your compressor. Check for condensation and unusual noises that could signal underlying issues. If you have access to the service manual, refer to it for specific measurements of electrical components. A simple current draw test can reveal if the compressor is working within specifications. To assist with your inspection, consider using a checklist that includes:

- Visual inspection for damage

- Checking electrical connections

- Measuring voltage and amperage

- Testing for ground faults

- Monitoring for unusual sounds and vibrations

By following these steps, you’ll ensure a thorough assessment of your compressor’s condition.

Essential Tools and Techniques for Accurate Diagnosis

To accurately diagnose issues with an HVAC compressor, having the right tools is crucial. Begin with a reliable multimeter to measure voltage and amperage, ensuring the unit is receiving adequate power. Pair it with a manifold gauge set, which helps monitor the refrigerant pressure levels. This combination can quickly highlight potential electrical or mechanical failures. Additional tools like a callibration thermometer can confirm that the temperature differential across the evaporator and condenser coils is within acceptable limits, helping pinpoint the issue more precisely.

In addition to tools, employing effective techniques can enhance your diagnostic process. Visual inspection is a fundamental step—look for loose wiring, burnt connections, or signs of physical damage to the compressor. Ensure that the disconnect switch is functional and that the power source is stable. Also, observe the compressor for abnormal sounds during operation, which may indicate internal malfunctions. As you gather data, record your findings in a simple table format:

| Observation | Action |

|---|---|

| Voltage Readings | Check wiring and fuses |

| Refrigerant Pressure | Assess for leaks |

| Sound Diagnostics | Inspect internal components |

Q&A

Q&A: Inspecting Your HVAC Compressor for Power

Q1: What is the role of the HVAC compressor in the heating and cooling system?

A1: The HVAC compressor serves as the heart of your system, moving refrigerant through the coils to transfer heat. It compresses the refrigerant and helps circulate it to absorb heat from inside your home and expel it outside, or vice versa depending on the season. Without it functioning correctly, your heating and cooling system can’t operate efficiently.

Q2: Why is it important to inspect the HVAC compressor for power?

A2: Inspecting the HVAC compressor for power is crucial as it ensures the system is functioning properly. A lack of power can indicate electrical issues, failed components, or might signal that your thermostat isn’t functioning correctly. Addressing power issues early can prevent further damage or costly repairs down the line.

Q3: What tools do I need to inspect the HVAC compressor?

A3: For a basic inspection, you’ll need a multimeter to check voltage, an insulated screwdriver, and safety gloves. Additionally, a flashlight can help illuminate dark areas, and duct tape can assist in securing loose wires if necessary.

Q4: How can I initiate the inspection of my HVAC compressor?

A4: Step one is to ensure your safety. Turn off the power to your HVAC system at the breaker box to avoid any electrical hazards. Once powered down, locate your compressor — usually found outside in a weatherproof unit.

Q5: What should I look for when inspecting the power supply to the compressor?

A5: Examine the wiring for any visible signs of wear, burns, or frays. Use the multimeter to check for voltage at the compressor terminals while ensuring the system is still off. When powered back on, check that you are receiving the manufacturer-recommended voltage. If not, there may be an electrical issue that requires attention.

Q6: How can I tell if the compressor itself is faulty?

A6: After verifying power, listen for any unusual sounds when the system attempts to start. A humming sound without operation could indicate a locked rotor, while a quiet, inactive compressor may suggest other failures. Observing whether the compressor is excessively hot or showing physical damage can also be key indicators of a problem.

Q7: What should I do if I discover power issues with the compressor?

A7: If power issues arise, it might be best to consult with a professional HVAC technician. They can diagnose the issue accurately and safely, whether it requires replacing wires, fixing the capacitor, or potentially replacing the compressor. DIY fixes on electrical components can be risky without the right knowledge.

Q8: Can regular inspections prevent future power issues?

A8: Absolutely! Regular maintenance checks can catch potential issues before they escalate. Cleaning the unit, ensuring proper airflow, and checking electrical connections routinely can help extend the lifespan of your HVAC system and reduce the likelihood of major failures.

Q9: What are some signs I should look out for that might indicate my compressor needs inspection?

A9: If you notice irregular sounds, inconsistent temperature levels, unusual odors, or frequent cycling on and off, these could be signs that your compressor needs urgent attention. Keeping an eye on your energy bills is also wise; sudden spikes could indicate inefficiency often linked to compressor issues.

Q10: Any final tips for maintaining my HVAC compressor?

A10: Certainly! Regularly change your air filters to promote efficient airflow, keep the exterior of the compressor clean and clear of debris, and schedule annual inspections with a certified technician. These steps can keep your system operating smoothly and prevent unexpected breakdowns.

By understanding the importance of your HVAC compressor and how to inspect it for power, you can ensure a well-functioning system year-round. Regular maintenance can save you time, money, and discomfort in extreme weather conditions!

In Conclusion

understanding how to inspect your HVAC compressor for power is not just a technical task, but an essential skill for maintaining a comfortable and efficient living environment. By following the steps outlined in this guide, you equip yourself with the knowledge to troubleshoot potential issues and ensure your system operates smoothly. Remember, a well-maintained HVAC compressor not only enhances performance but also extends the lifespan of your system, saving you both time and money in the long run. With safety as your priority and diligence as your companion, you can confidently navigate the intricacies of HVAC maintenance. Embrace the journey of learning and empower yourself to keep your home’s climate control functioning optimally. Your comfort is worth it!