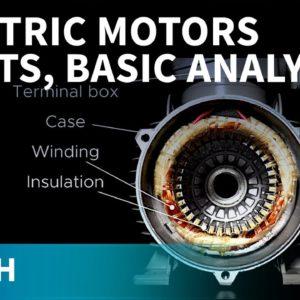

Hello and welcome to this video about the

failure and analysis of asynchronous motors. Asynchronous motors are the most common type of

motors used. They are known for their advantages such as low purchase price, high efficiency, easy

regulation and simple but robust construction. Despite their high reliability, asynchronous

motors suffer from some malfunctions of machine parts. We can divide failures in

an asynchronous motor into failures of mechanical and electrical origin, as well

as stator, rotor and bearing failures. Let´s start with the bearings.

All parts of the bearing are subject to degradation. The cause of bearing failures can be

considered as mechanical stress during rotational movement and bearing currents. Mechanical

stress can be caused by poor installation, poor assembling, or by improper use,

overloading, and poor maintenance. The bearing currents can

be caused by shaft voltages (due to asymmetric electrical circuits or

power supplies) and capacitive currents (caused by the pulse frequency from the power

supply control of semiconductor converters). All mechanical (and some electrical)

motor faults have a unique signature in the vibration spectrum of the machine

and vibration analysis can recognize them. Failures such as misalignment, looseness,

unbalance and bearing faults are diagnosed according to the same rules applicable

for all other machinery parts. How do we analyze mechanical faults? Get the

answer for example from our video named How to become an expert in Vibration Analysis and our

other tutorial videos.

What is vibration analysis? Our series of Vibration analysis for beginners

videos will help you to understand this topic. Some electrical faults are recognizable

in the vibration spectrum too. You should measure the motor with and

without a power supply in order to find them. Some vibration signatures could disappear after

power off – those with an electrical origin. You can also focus on the exact

frequency of peaks in the spectrum. If you find a peak with your exact current

supply frequency (for example 50Hz and more often on its harmonic frequencies) it is probably

an electric issue because there is always some slip on a loaded electric motor and the motor

isn´t running on its exact rotation frequency. Electrical (and some mechanical)

motor faults have a unique signature in the frequency spectrum of the motor

current. The MCSA method can recognize them. MCSA stands for: Motor Current Signature Analysis. Excessive sidebands are created in electric

motors, which distort the frequency spectrum. Each fault then has its specific signature.

Individual defects can be distinguished from each other according to the amplitude

bands and the frequency or other signatures. The basis of this method is to measure the

course of the stator current of one or more phases in the time domain and

its subsequent spectral analysis.

Stator faults

Stator winding faults cause the majority problems in stators. Broken winding

insulation is the most common stator fault. MCSA can recognize broken

insulation between threads, which can lead to broken insulation between

phases and it is fatal for the motor. Thermal stress has the greatest impact

on the life and quality of insulation. Another undesirable effect is the

electrical stress of the transient voltage. In the case of more and more frequent

use of inverters for soft-start, rectangular voltage pulses are

modulated at the output of the inverter. Rotor faults

The rotor of an asynchronous motor consists of a shaft, insulated sheets pressed on

the shaft which form the rotor magnetic circuit and windings. Mostly the winding of

the rotor consists of a cage structure, which is formed by bars, which

are connected at the ends. Rotor eccentricity (meaning the unevenness of

the air gap between the rotor and the stator) and rotor bar interruption

are the most common faults. The cause of these faults can be

the use of poor-quality materials, overloading or heavy starts. In the case of rotor bars, the fault may increase

the resistance of the bar, or completely break the bar electrical circuit.

Rotor bar failures

result mainly in engine starting deterioration and generating parasitic moments. Also, the broken

bar causes additional faults in other bars because the current in them is greater due to the missing

bar current path (where one bar is broken). The ADASH VA5Pro vibration analyzer offers

the unique capability of analyzing vibration and current in one device. In addition, the MCSA

module expands the capabilities of the analyzer and allows you to do analysis of the current

signature from the spectrum – based on your knowledge and experience, or you can use the

automatic detection function. It is a similar feature to the ADASH automatic Fault Source

Identification Tool (FASIT) for vibration analysis. The device can automatically recognize

the main causes of failures such as unbalance, looseness, misalignment and bearing faults.

The MCSA module of the VA5Pro device is able to automatically identify rotor and stator faults,

eccentricity, broken rotor bars and power quality.