Introduction to Centralized Air Conditioning Systems

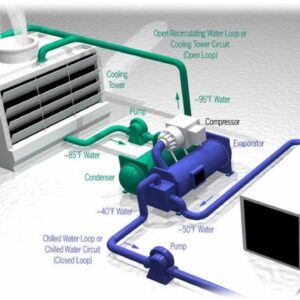

Centralized air conditioning systems are a popular choice for large cooling capacity, usually in commercial settings. A chiller system consists of three main cycles: the refrigerant cycle, chilled water cycle, and condensed water cycle. The components involved in these cycles work together to efficiently cool an entire building, making the centralized air conditioning system a practical and energy-saving option. In this article, we will examine each of these cycles in greater detail, explaining the function and importance of their respective components.

Refrigerant Cycle

Compressor

The refrigerant cycle consists of four basic components: the compressor, condenser, expansion device, and evaporator. An additional component, called a filter dryer, is also included in the system. The compressor’s primary function is to increase the pressure of the refrigerant, which in turn raises its temperature higher than that of the condenser water. This heat transfer is essential for regulating temperatures within a centralized air conditioning system.

Condenser

Refrigerant in high-pressure gas form enters the condenser, where heat is eliminated to the condenser water from the cooling tower through convection and conduction processes. As the refrigerant’s heat is removed, it condenses into a high-pressure liquid before exiting the condenser.

Filter Dryer

An additional component called a filter dryer is included in the refrigerant cycle. Its purpose is to filter dirt and absorb any moisture in the refrigerant, ensuring it is clean and dry before entering the expansion valve.

Expansion Valve

The expansion valve serves to reduce pressure and control the flow of refrigerant entering the evaporator. As the refrigerant’s pressure decreases, its temperature also drops, allowing it to absorb heat from the chilled water in the centralized system.

Evaporator

Low-pressure liquid refrigerant from the expansion valve flows into the evaporator. Heat from the chilled water in the air handling unit is absorbed by the refrigerant, causing it to evaporate into a low-pressure gas. This gas then returns to the compressor, completing the refrigerant cycle.

Chilled Water Cycle

Air Handling Unit

The chilled water cycle consists of two primary components: the air handling unit and the water pump. The air handling unit is responsible for generating cool air and distributing it throughout the building. It comprises several essential parts, such as cooling coil, fan, fan motor, belting, filters, and the casing.

Water Pump

The water pump in the chilled water cycle circulates chilled water between the evaporator and the air handling unit. This flow ensures continuous cooling and temperature control within the building.

Condensed Water Cycle

Cooling Tower

The cooling tower in the condensed water cycle is tasked with cooling condenser water. Key components of the cooling tower include the motor, sprinkler blade, water fin, water reservoir, buoys, and a make-up water tank.

Condenser Water Pump

The condenser water pump helps move condenser water between the chiller and the cooling tower. As the water flows through the system, it absorbs heat from the refrigerant, effectively lowering the temperatures throughout the building.

Centralized Air Conditioning System: A Practical and Efficient Solution

By understanding the components and cycles involved in centralized air conditioning systems, one can better appreciate their practicality and efficiency. These systems are particularly beneficial for large commercial spaces, where the need for consistent temperature control and energy-saving measures are essential. In conclusion, centralized air conditioning systems offer a reliable and effective solution for managing the cooling needs of large buildings.